PYROCO2: Revolutionizing Chemical Production with Climate-Friendly Technology

For climate-friendly solutions in chemical production, PYROCO2 is developing carbon capture and utilisation technology.

We must quickly adopt cutting-edge, climate-friendly solutions that can energize and transform the market if we want to achieve climate neutrality by 2050. Emerging methods for carbon capture, utilization, and storage (CCUS) show great promise for lowering emissions in the chemical and different industries while also producing value from CO2, its main and most expensive side stream.

The goal of carbon capture and storage (CCS) is the long-term, extensive storage of professional carbon emissions. In contrast, carbon capture and utilization (CCU) aims to reduce reliance on carbon from biomass or fossil sources by valorizing them in the form of new business products. As a result, in the context of efficient carbon management, CCS and CCU play important roles as climate action and bioresource relief. The PYROCO2 project transforms the lives of carbon-intensive businesses by laying the groundwork for the sustainability of the chemical sector in Europe.

PYROCO2: Cutting-Edge Biotechnology-Based Carbon Capture And Exploitation For The Production Of Acetone That Benefits The Environment

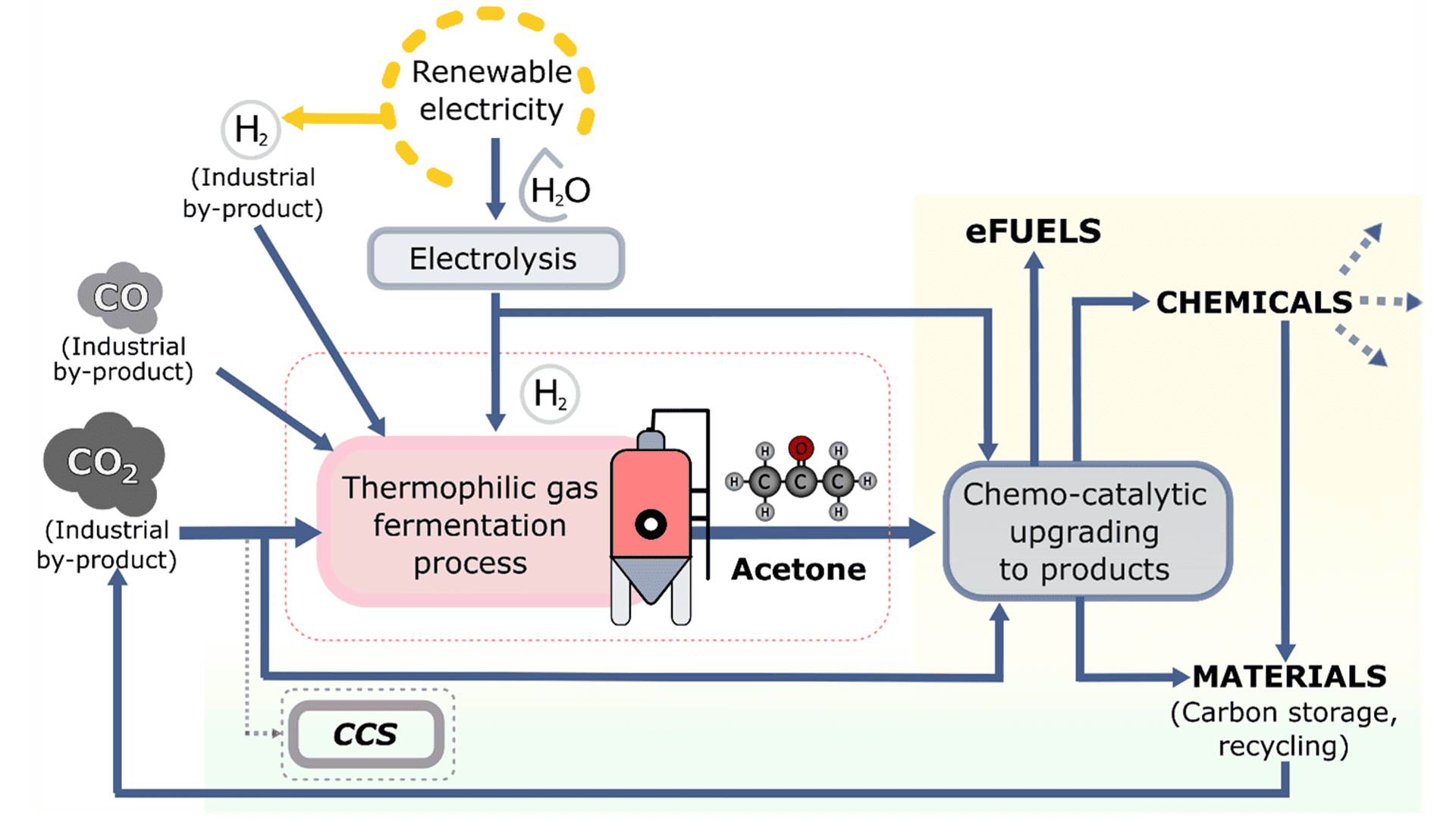

PYROCO2 is leading the way in proving the viability and economy of carbon capture and utilization to produce hydrogen from renewable energy sources and climate-positive acetone from professional CO2. An energy-efficient thermophilic bacterial bioprocess is at the core of this technology, poised to reduce an impressive 17 million tonnes of CO2 equivalent emissions by 2050. The PYROCO2 process produces acetone, which allows the production of a variety of chemicals, synthetic fuels, and materials from CO2, creating a wide range of pre-developed processes across several value tiers and practical business opportunities that are prepared for replication and commercialization.

A crucial substance in the chemical industry is acetone, (CH3)2CO. The clear, colorless, turbulent, and flammable liquid with a boiling point of 56°C is the simplest and most popular example of the ketones chemical group. Acetone is a typical building block in organic chemistry and is totally solvent with water, the majority of natural solvents, and oils. It is generally used in industry to synthesize bisphenol A and methacrylates. Additionally, it is employed as a solvent in numerous business processes, including the creation of plastics and synthetic fibers, resin thinning, the preparation of metal before painting or soldering, and the blending of volatiles in paints. In 2019, there was a 7.4 million tonnes of acetone in the world, with Asia accounting for about 52% of all international consumption. Today, professional acetone production is almost entirely from fossil resources as a by-product from, and thus linked to, acid production using the cumene process. The European market share of approximately 21% was almost 1.6 million tonnes in 2019. During World War I, the Weizman process, which produces acetone from sugars on a large scale and sustainably using aerobic bacteria, was also established. However, it was ultimately abandoned and almost totally replaced by newer techniques based on fossil resources that had better yields and economics, despite their low sustainability. Production of acetones in Europe releases roughly. The estimated 1.4 million tonnes of monthly German acetone production are equivalent to 2.3 million tons of CO2. The chemical compound for which production will be shown at scales of upward to 4,000 t/a and the PYROCO2 biological production platform’s main transitional is acetone.

For any innovative technology that wants to change the market, technology validation at a demonstration scale is essential. In light of this, the PYROCO2 project’s primary goal is the design and construction of a chemical production demonstration plant that enables at-scale optimization and validation of the technology as it moves toward industrial scale. It will further demonstrate how new technologies that use CO2 and reduce pollution can be made possible by coordinated teamwork and near collaboration between Western carbon-intensive industries and some of Europe’s top research institutions and universities. The objective is to show that it is feasible to use heat-thriving microorganisms to effectively and particularly transform CO2 and renewable electricity-derived hydrogen into acetone for the purpose of demonstrating product diversification into various markets.

Plant For Demonstration

The PYROCO2 demonstrator plant is intended to be strategically located in southeastern Norway’s Herøya Industrial Park. The Herøya peninsula is home to Norway’s largest technological cluster, along with nearby industrial areas. The capture of 400,000 tonnes of CO2 in this area is expected to begin in 2024 as part of the extensive CCS project “Northern Lights,” which is a component of “Longship,” the full-scale carbon capture and storage project run by the Norwegian government. Herøya Industrial Park and its clients, which use the reasonably priced, 100% clean grid electricity,place a high priority on sustainability and decarbonization. CCUS is being assessed as a substitute for both adult plants and in-joint solutions in parallel.

The PYROCO2 demonstrator plant in Herøya is expected to be able to produce up to 4,000 tonnes of acetone annually while using 9,100 tons of business CO2 and green hydrogen. The location promotes technological symbiosis by fusing several carbon-intensive industries with biochemical production while ensuring plentiful and flexible access to CO2 feedstock from various industrial sources, and green energy. This project represents a major step toward Europe’s future becoming greener and more prosperous.

Significant Effects Of The Project

PYROCO2 is set to achieve crucial goals, including creating a large-scale demonstrator by 2026. This demo will exemplify how different industries, like medical and technological gases, fertilizers, cement, metallurgy, hydrogen, chemicals, polymers, and chemical fuels, can work together effectively under Industrial Biotechnology. This project aims to reduce business CO2 emissions significantly compared to standard acetone production methods. PYROCO2 will play a significant role in helping the EU’s chemical industry move towards climate neutrality by introducing a cost-effective, eco-friendly process to make important chemicals and other products. The project will even prove that the production of acetone through the PYROCO2 process is versatile, feedstock-accommodating, and cost-effective, paving the way for similar projects across Europe. Moreover, it aligns with the EU’s efforts to reduce air pollution, ensuring the well-being of EU citizens by cutting emissions and promoting a cleaner environment.

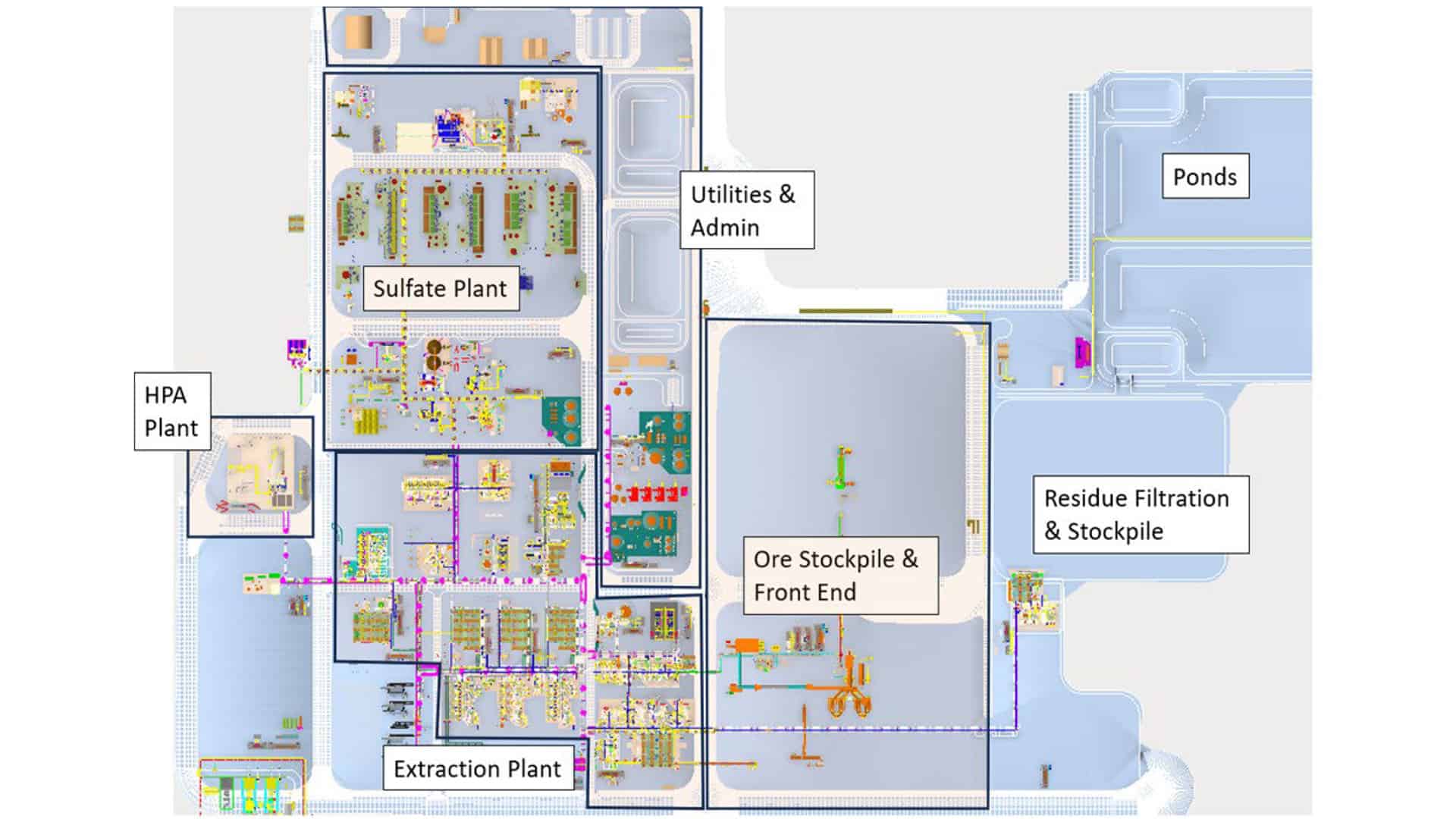

Herøya Industrial Park, the technological environment for the construction and operation of the PYROCO2 demonstrator plant

The PYROCO2 Consortium

PYROCO2 brings together a consortium of 20 partners from ten European countries, with broad geographical coverage that extends to Thailand as the project’s referral to the Asian market. This diverse collaboration includes eight major enterprises (Arkema (FR), DSM-Firmenich (CH), SCG Chemicals (TH), Johnson Matthey (UK), NextChem (IT), PNO-CiaoTech (IT), Herøya Industrial Park (NO), and Bioprocess Technology (ES)), three innovative SMEs (AGAIN (DK), Ranido (CZ), Ecoinnovazione (IT)), four leading academic institutions (Chalmers University of Technology (SE), Technical University of Denmark (DK), University of Lyon 1/National Centre for Scientific Research CNRS (FR), Karlsruhe Institute of Technology (DE)), three Norwegian Research and Technology Organisations (SINTEF, NORCE, NORNER), the Public-Private Cluster AXELERA (FR), and the regional authority Vestfold and Telemark County Council (NO). The project assembles leading entities across Europe, encompassing a complete range of expertise required to achieve the ambitious goal of demonstrating a novel, green, and financially viable pathway from industrial carbon emissions and green electricity to the key chemical acetone and from that onward to various other chemicals, as well as materials and synthetic fuel products, typically reliant on fossil feedstock.

PYROCO2: Leading the way in green innovations and achieving extraordinary milestones

While completely conceptualized and established under COVID-19 restrictions, the five-year PYROCO2 project was funded and officially launched in October 2021. With its nearly €44m budget and an EC contribution of €40m, it represents one of the largest projects funded under the Western Horizon 2020 Research and Innovation program’s call for proposals in support of the European Green Deal, the coordinated effort to make Europe climate neutral by 2050.

Important facts about PYROCO2:

- Funding programme: Horizon 2020

- Call for proposals: LC-GD-3-1-2020: Closing the professional carbon cycle to combat climate change – Industrial feasibility of catalytic routes for sustainable alternatives to fossil resources

- Project type: Innovation action

- Technology Readiness Level range: four/five to seven

- Project period: 60 months, October 2021 to September 2026

- Budget for the entire project: €44m

- EC contribution: €40 million

- 20 individuals from 11 nations make up the partners: Norway (5), France (3), Italy (3), Denmark (2), Sweden, Germany, United Kingdom, Czech Republic, Spain, Switzerland, and Thailand

- Ranked second in EC’s choice for the GD-3-1 topic.

- The fourth-largest grant was given out in Horizon 2020 in 2021.

- The standard project will begin on October 1st, 2021.

- Website: www.pyroco2.eu

References

- May 2020 ICIS Top 100 Chemical Distributors. Analyst the acetone market in Europe.

- Trends in the Acetone Market, Demand 2020–2027. Data and reports.