The recent introduction of the hydrogen-powered Toyota Hilux at Cenex‘s Low Carbon Vehicle and Connected Autonomous Mobility 2023 has been hailed as a significant development for the Light Duty Vehicle ( LDV ) and Light Commercial Vehicles( LCV ), respectively.

The new powertrain, which is based on the classic Hilux chassis, makes use of essential components from the Toyota Mirai hydrogen fuel cell electric saloon, a technology that has been used for nearly ten years in commercial production to demonstrate its quality and dependability. The fuel cell only emits natural water tailpipe emissions when it is driven. Ten prototypes will be produced for the project in Derbyshire, with some serving as customer demonstrators and the remaining ones being used for stable and active testing to make sure the vehicle can meet the stringent requirements of a production model. If powerful, it might create new opportunities for UK industry.

Toyota Hilux: Advancing Automotive Industry Decarbonization with Fuel Cell Technology

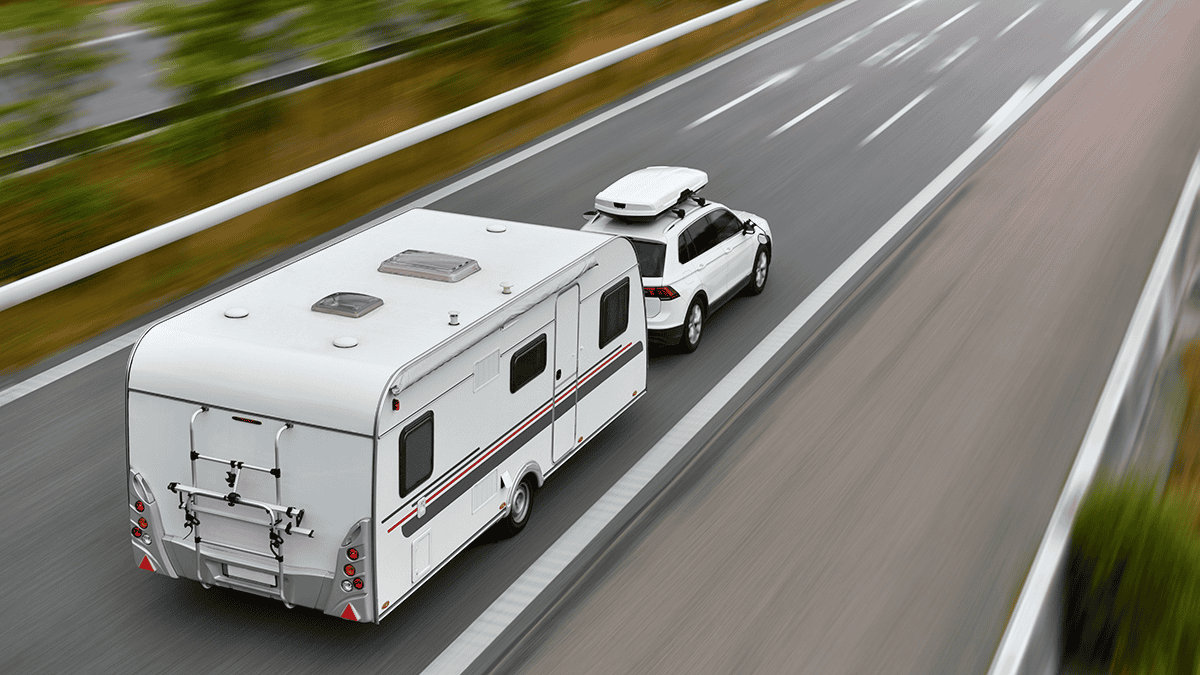

The Toyota Hilux and other similar vehicles are used in a wide range of settings, both on – and off-road, as well as for many different purposes, including people movement, utility-based services, and emergency response. This is a fantastic choice powertrain system for end users and customers who support larger initiatives of businesses to lessen their environmental impact.

Speaking about the ground-breaking vehicle, Nusrat Ghani, Minister for Industry and Economic Security, remarked:” The UK has an incredible manufacturing sector, and this is another great example. I applaud the project team for their accomplishments in this ground-breaking development, and it’s wonderful to see Toyota make another step toward achieving zero emissions in Britain.

The UK is setting the standard for next-generation car manufacturing, and this is yet another illustration of how the UK Government’s support is assisting our mechanical sector in accelerating toward online zero emissions.

How will this accomplishment help the industry achieve its goal of decarbonization and how will it open up new opportunities for it?

The Toyota Hilux’s significance

First, it is wise to consider how the industry is currently using Internal Combustion Engine ( ICE )- led LCV and LDV units in order to comprehend the significance of the development of this Toyota Hilux, which was funded by a£ 5.6 million government grant distributed through the Advanced Propulsion Centre UK’s( APC ) Collaborative Research and Development funding stream(£ 11.4 million total project funding ).

According to a Statista report, the pick-up truck market will experience revenues of$ 117.1 million (approximately £94 million ) in 2023, and 1.48% growth by 2027.

22, 205 new pick-up trucks have been sold so far in the UK in 2023, according to data from the Society of Motor Manufacturers and Traders( SMMT ). According to a report from SP Global, there will be 248,000 new light goods vehicle registrations in 2022.

The difficulties of a hydrogen-powered pick-up truck

Some of these registrations are occurring in the business world. Pick-up trucks are the foundation of many remote businesses. For instance, pick-up trucks are used in the forestry sector to travel across large, frequently uneven terrain, where getting to and from each location may take several hours while covering many hundreds of miles in a single day.

Recharging a battery would consume beneficial working time and result in high business costs. Similar circumstances exist in the mining sector, where it is possible to charge an electric vehicle on-site at a quarry or mine. However, given the logistics of such operations, this would likely necessitate supplying the battery-electric vehicle ( BEV ) charger with the electricity it requires. Of course, this would defeat the benefit of having a” green” vehicle solution.

Trades like the construction industry or agricultural services would likewise clearly benefit from a hydrogen-fueled vehicle’s ability to rapidly refuel on the go between jobs and further boosting productivity and profitability when we consider industrial use, pick-ups, and another LCVs that are used in the delivery and transport of tools and materials.

Toyota Hilux Hydrogen Prototype: Revolutionizing Refueling for Light Duty Vehicles

With this in mind, it is probably apparent that one of the most important queries raised by people who use cars in this way is about the timing of refueling. A standard petrol or diesel ICE vehicle can now have its tank refilled in a matter of minutes. For consumers who don’t have flexibility in their travel times or businesses that need to be constantly on the road during working hours, the downtime for recharging a BEV presents notably of an planning conundrum.

In this regard, hydrogen-fueled vehicles are much more strongly foe to ICE vehicles, with refueling times commonly measured to be under ten minutes, depending on tank size. For instance, the Toyota Hilux prototype requires less than five minutes to refuel.

What we’re looking at is a classic Hilux, powered by an 80 kilowatt fuel cell, with seven kilograms of hydrogen storage, giving it an operating range of 350 to 400 miles, according to Richard Kenworthy, managing director of Toyota Motor Manufacturing UK. It can refuel in less than five minutes, which is the most important feature.

Pioneering the Future of Hydrogen-Powered Light Duty Vehicles

The development of the Toyota Hilux demonstrates that there is a professional capacity to deliver all the utility of an ICE pick-up along with all of hydrogen’s environmentally friendly benefits in one economically feasible package. You have the foundation for a real step-change in the light duty vehicle sector, which will begin to quickly develop over the next few years, when combined with the desire from industry and commitment from the government to provide the necessary infrastructure to keep them running on the road.

As hydrogen refueling networks grow and hydrogen at the pump drops to$ 4 – 5 / kg, the APC predicts rapid growth in fuel cell platforms for light duty vehicles starting in 2030. Can the UK afford never to invest in hydrogen? is as detailed in our report. By 2035, we anticipate that 400, 000 hydrogen carbon fiber tanks and 14GW of on-board fuel stack power will be needed to meet the demands of Fuel Cell Electric Vehicle ( FCEV ) production in the UK alone. That is 140, 000 vehicles’ worth of value.

Reduced costs are possible.

The current price of making the battery pack, nonetheless, is the biggest obstacle to the widespread adoption of hydrogen fuel cell vehicles. How can it be done, according to a new APC report, to lower the cost of fuel cells? ” Details that by 2030, hydrogen vehicles must achieve a cost basis of$ 80 per kWh in order to achieve near parity with BEVs.” Assuming 94 kWh of usable energy in a light-duty FCEV, it currently costs between$ 120 and 130 per unit.

The major cost-cutting factor for the fuel cell stack and system is anticipated to be economies of scale. According to the APC report, costs could be reduced as low as$ 86 kWh by 2030 at a single manufacturer location producing 500, 000 units.

The remaining gap should be filled by performance enhancements and material innovations, which are also anticipated to have a significant impact on the cost of $/ kWh.

This means that in the not too distant future, fuel cell powertrains may be a cost-effective comparable solution to batteries for some use cases, such as larger SUVs and vans.

The upcoming generation of the UK mechanical sector

Speaking about the Toyota Hilux project, the implications, and the potential prospects for the UK as a destination for hydrogen fuel cell vehicle and component production, Ian Constance, APC Chief Executive Officer, said:

A hydrogen fuel cell vehicle has been designed, integrated, and delivered as part of the Toyota Hilux project, which is a great illustration of collaborative research and development. The APC anchors capability in D.C., which helps protect and create new jobs in the future, is funded by the UK government. It incorporates the newest net-zero technologies and vehicles into the UK.

” The project consortium has made great strides in delivering a number of vehicle demonstrators that were created and constructed in the UK. Within a year of the project’s beginning, the prototype hydrogen fuel cell Toyota Hilux worldwide launch serves as an unmistakable testament to the capabilities and strengths of UK automotive supply chains.

” We already have 15 % of the fuel cell value chain emanating from UK businesses, but this could increase to as much as 65 % just by building on our current electrochemistry and coatings strengths or using our automotive capability to mass produce parts like stack assemblies and bipolar plates.”

Conclusion on UK’s Innovative Approach: Integrating Hydrogen Fuel Cell Technology into Light Duty Vehicles

It is a major step forward and something that hasn’t been done before to demonstrate the ability of integrating an associated hydrogen fuel cell and related technologies into the design of this type of vehicle. The creative nature of this APC-funded project and the strategy used to deliver an other powertrain solution offer another choice for a sizable customer base for this kind of vehicle.

Through additional investment, the development of new skills, and job retention, this project has also demonstrated the UK’s strong position in terms of engineering skills and supply chain resilience.

The UK’s transition to net zero will necessitate the use of alternate powertrains by all vehicle types. The UK is in a powerful position to deliver the necessary solutions and is leading the way in terms of engineering, design, manufacturing, supply chain, and skills as vehicle manufacturers develop the technology and demonstrate integration into various vehicle platforms along with rising customer demand.