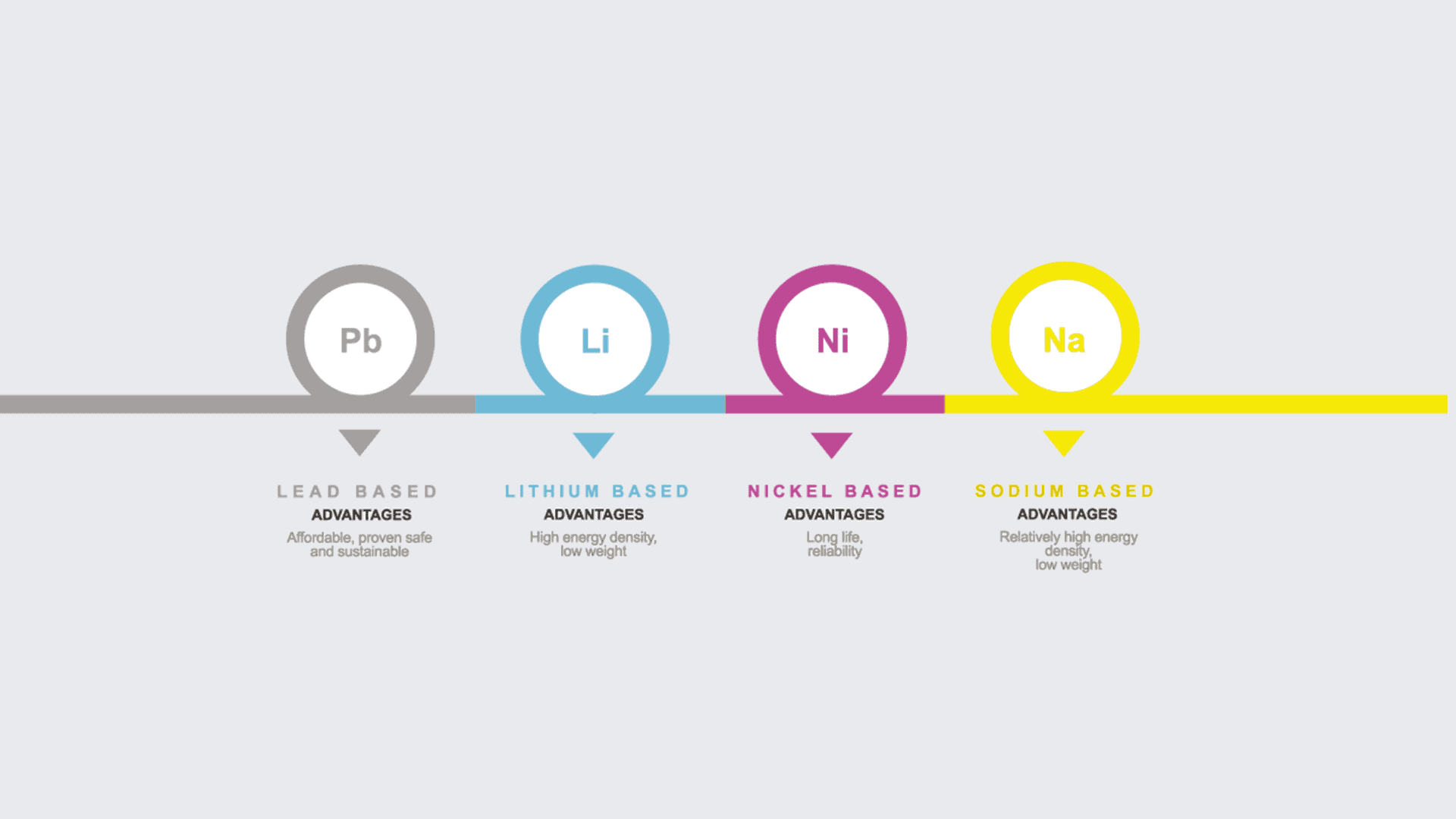

The association of Automotive and Industrial Battery Manufacturers and their subcontractors in Europe, the Middle East, and Africa is known as Eurobat. EUROBAT, which also represents the German battery industry, covers all common battery chemistries on the market, including lithium, lead, nickel, and sodium.

The development of a trusted, longer-lasting electricity source that could produce dependable energy and power output was the main driving force behind battery innovation in the 19th century. This effort led to the development of lead-based battery products, a technology that has stood the test of time and is also properly applied in modern applications.

The need for Uninterruptible Power Supplies( UPS ) and the emerging applications of the time, such as portable electronics, telecommunication, automotive vehicles, railway rolling stock, aviation, ships and submarines, and satellites were what fueled battery innovation in the 20th century. Each application required more particular battery qualities, which led to a wide range of battery products. Due to their higher energy density and fairly low weight, the development of lithium-ion batteries in the late 20th century complemented the widely used, cost-effective, and secure lead-based technologies.

The factors influencing battery innovation today are more varied and intricate. In addition to being optimized with particular qualities for particular applications, batteries are also created to meet European standards for the environment, energy independence, the security of the supply of raw materials, and the more electrification of transportation and other industries. In light of this new situation, EUROBAT launched a 2030 White Paper Batteries Innovation Roadmap. In order to re-evaluate the market and technological developments for all four well-known and encouraging technologies in relation to the applications they serve, this was updated in June 2022.

The roadmap demonstrates the cutting-edge and innovative potential of each of the major chemistries:

R & amp, D for lead-based batteries

The development of lead-based batteries is still crucial, particularly with the introduction of novel, cutting-edge materials( such as chemical expanders, nanobased carbon materials, new alloy compositions, and improved battery design ).

Their potential lies in application-specific innovation, such as enhancing automotive active charge acceptance at unmatched higher temperature durability. Similar to this, they may be crucial in enhancing energy and power densities with improved cycle life for particular industrial applications in the field of fixed and off-road transportation.

Batteries made of Thin Plate Pure Lead( TPPL ), Bipolar, and Carbon Enhanced Lead Acid are promising candidates for PSOC operation, improved power density, or longer service life. The fact that these enhancements have been tailored to specific applications is what makes this process exceptional.

By 2030, this battery chemistry will be in the lead for particular mechanical and commercial applications thanks to the introduction of smart battery operation modes, which also has the potential to improve the electrolytes, materials, and components used.

R & amp, D for lithium-based batteries

E-mobility is now the most appealing technology and the main requirement for higher energy densities to achieve increased driving range. This leads to a 2030 development roadmap that primarily focuses on lithium-based technologies based on modified nickel-cobalt manganese oxide( NMC ) materials, which combine high capacitive anode materials with carbon / silicon composites with increased nickel and reduced cobal content. Additionally, good state technology aims to boost energy density and enhance safety.

The resulting Li-ion batteries exhibit distinct and unique performance characteristics suitable for various kinds of applications due to the variety of possible combinations of cathode and anodes materials.

In terms of other material research, activating extraction processes, morally good mining, recycling, and safety, the development of Li – ion technologies suited for business and electrical applications is still a challenge.

In addition to NMC-based lithium-ion technology, LFP( Lithium Iron Phosphate ) is preferred for stationary applications because of its long cycle life. R & amp is moving D in the direction of” intrinsically safe” lithium manganese iron phosphate( LMFP ) with a higher energy density. Important natural materials like nickel and cobalt are absent from both LFP and LMFP.

R & amp, D, nickel-based battery

Nickel-based batteries( nickel cadmium and nickel metallhydrid( NiMH ) are still used in specialized and niche applications, with various designs, as a result of decades of safe use under the most extreme climates, cycling, and / or fast charging operating conditions.

Due to its essential performance characteristics under extraordinary circumstances, the technology can be more developed for both existing applications and as a replacement solution. Over the next ten years, nickel-based batteries are one of the electrical storage systems that should be taken into account for continued use in specific industrial applications.

Sodium-based battery R & amp, D

High-temperature nickel-based batteries( operation temperature and gauge, 300 ° C ) are made up of liquid electrodes and a solid electrolyte, in contrast to other battery types. The sodium nickel chloride ( NaNiCl ) and sodium – sulphur battery( SaS ), which are used in stationary larger back-up power and load-leveling applications, are commercially available representatives.

Regarding energy efficiency( thermal losses from heating required to maintain cell temperature ) and internal resistance( which is positive for NaNiCl ), both technologies still have room to improve. The large demand for nickel and the intricate flexible construction are additional factors to research and take into account.

The promising drop-in technology of room temperature Sodium-Ion battery( SIB ) is currently the main focus of sodium-based battery R & amp, D. The operating principle is superior to that of Li-Ion batteries, with the use of non-critical materials and the potential for lower costs being the main advantages in comparison.

Roadmap for EUROBAT Innovation 2.0

The current Roadmap for EUROBAT Innovation 2.0 also takes into account the innovation potential of most promising technologies including: lead bipolar, sodium-ion room temperature, post-lithium-ion all solid state Gen. 4b and Gen. 4c, and Lithium Sulphur and Lithium-Air Gen 5. Regarding each, it is necessary to consider why it is important to continue their developments.

We can draw the conclusion that li-ion and lead-based batteries will continue to be the prominent battery technologies in 2030 by taking into account the anticipated timelines for both increasing European production capabilities and for innovations to enter the market, as well as promising new market predictions( demand side ).

A world battery market of 4150 GWh is predicted by the Avicenne report published in September 2023, which was commissioned by EUROBAT. Of this market, 3360 of the batteries are lithium-based, and 774 of them are lead based technologies.

A living document is the EUROBAT Batteries Innovation Roadmap.

During the EUROBAT Annual Event in Brussels from June 4 to 5, 2024, we anticipate the release of a second edition. We will be able to assess the effects of various EU policy initiatives and fresh legislation that have been put in place since we released the roadmap 2.0 in this document.

The European Battery Alliance ( EBA ) of the European Commission is supported by EUROBAT, which aims to stay at the forefront of technological advancements in a variety of industries. For all technologies, from raw materials to battery pack production, this entails increasing competitive and long-lasting local production capacities.

significant obstacles to address

We can already confirm that, whether or not with governmental and / or private-led R & amp, D funds, our technology leadership— which we will describe in the upcoming update— will involve new areas of innovation, such as manufacturing processes and recycling, and strongly focus on developing a circular economy and incorporating sustainability aspects.

Data management, digitalization, and standardization needs( implementation of the battery mandate M / 579 and future improvements to the Battery Passport ) are additional transversal issues and significant challenges that R & amp, D must address in order to better direct waste streams, meet higher collection rates( all elements ), and maximize the use of recycled primary and secondary materials in new batteries.

R & amp, D on battery integration in many applications, as well as investments to scale up manufacturing of clean technologies( including battery manufacturing ), will be drawn in by the recently introduced Net-Zero Industry Act as part of the Green Deal Industrial Plan and the reform of electricity market design. In other words, we must overcome the obstacles that the German battery manufacturing industry faces in order to succeed.