Project Trident is leading the charge in developing zero-emission heavy-duty vehicles through innovative propulsion technologies. Supported by the Advanced Propulsion Centre UK (APC), the project focuses on e-turbo propulsion systems, which are redefining the efficiency of internal combustion engines (ICE) and hydrogen fuel cell technology. E-turbos offer revolutionary performance improvements for heavy-duty vehicles like freight trucks and buses, aiming to significantly reduce CO2 emissions and fuel consumption. By using advanced simulation and modeling tools, Project Trident enhances system-level efficiency across various thermal propulsion powertrains. The integration of e-turbos in heavy transport supports the UK’s commitment to decarbonizing the transport sector, a critical step toward achieving the 2050 net-zero goal. The project’s success underscores the potential of UK manufacturers to strengthen the local supply chain and bolster the mechanical sector through innovation. With a focus on performance, durability, and emissions reduction, e-turbo technology represents the future of eco-friendly heavy transport, helping the UK lead in sustainable transportation solutions. Project Trident’s groundbreaking advancements hold immense promise for the transportation industry’s green transformation.

The Advanced Propulsion Centre provides more information about Project Trident and its commitment to developing cutting-edge propulsion technologies capable of producing heavy-duty, zero-emission vehicles.

In the pursuit of decarbonisation, the transport industry stands at a critical juncture. Innovations in propulsion technologies have become necessary in light of the urgent need to reduce greenhouse gas emissions.

The UK mechanical sector has a commitment to the primary goal of reducing CO2 and harmful emissions from vehicle use by 2050 and the net zero target. Significant research and development is underway to develop zero-emission heavy-duty vehicles ( HDV), with the most recent and promising result being the e-turbo.

The Advanced Propulsion Centre UK ( APC ) Senior Project Delivery Lead, Gareth Purdy, examines a leading APC-supported project that is redefining the efficiency landscape of thermal propulsion powertrains, their application in heavy transport, and their key contribution.

The heavy-duty problem

The heavy-duty industry generates £15.8bn in revenue, £3bn Gross Value Added, and is responsible for British exports of £11.8bn, while European exports generate 39 % of revenue. The UK has several strengths in the heavy-duty market, particularly vehicle and engine research and development and manufacturing. The off-highway construction equipment sector in the UK is regarded as second in Europe and five in the world in particular. ¹

Vehicles that fall under the HDV category, 3.5 tonnes and below, have a far greater diversity than consumer-focused passenger cars and light-duty vehicle equivalents. Businesses treat these vehicles largely as capital equipment, valuing long life, durability, uptime, and utility. The reliability of the service is essential to maintaining supplier credibility. Some fleets ‘ reputation is a significant factor in their choice of vehicles, and customer perception may influence a quicker transition to a zero-emission fleet than businesses with less scrutiny from their customer base. There is much more customization of vehicles to fit the needs of each user. Within the weight categories, there is a broad spectrum of power, onsite energy storage, and refuelling, including remote fuelling needs.

Zero-emission technology solutions must be both practical and appropriate for the user case when considering the transition to net-zero heavy-duty vehicles. There is no one-size-fits-all approach that could replace the existing universality of diesel.

Project Trident

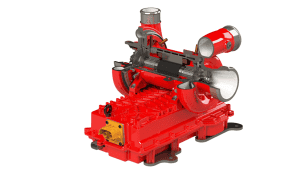

Electronic turbos (e-turbos ) are emerging as game-changers in internal combustion engines ( ICE ) and the promising realm of hydrogen fuel cell technology. In 2021, Cummins Ltd, Aeristech, Holtex, and the University of Bath ( IAAPS) were awarded £10m in government and industry funding through APC’s Collaborative Research Development competition, enabling the consortium to accelerate the development of air handling technologies for hybrid and fuel cell platforms. Working together, Cummins, Aeristech, Holtex, and IAAPS created the exclusive development of the tools and logical methodology needed for scale-up, the project was developed. The project created a base platform and an integrated architecture especially designed for e-machine componentry in this way. From this, the project realised integrated complete system prototypes and the correct series manufacturing and supply chain processes, which supported the delivery of customer-ready demonstrators.

One of the main outcomes of the project was the development of the supply chain through collaboration, which is a fundamental principle of the APC, and the UK’s integration of the novel capability and capacity to provide opportunities for the component value chain.

Trident’s extreme full-system approach joins up parallel technology, materials and manufacturing breakthroughs in all important components and subsystems through specialized modelling/scale-up tools. Using toolsets and special expertise, the project can realise destructive base aero, rotor-dynamic, and e-machine platforms and frequent architectures to effectively integrate all new technologies to greatest advantage. All of this while generating additional efficiency gains by utilizing tale effects from expanding the integration envelope to after treatment.

The project hopes to achieve significant CO2 and fuel consumption savings for ICE-based platforms like hybrids, natural gas vehicles, and reduced-emission diesel variants by redefining the sensible limits of system efficiency across multiple thermal propulsion powertrains as well as system level efficiency at the vehicle level.

E-turbos can look for new ways to improve their turbocharging technology’s efficiency and performance. E-turbos incorporate electrical motors to improve turbocharger performance, in contrast to standard turbochargers, which use exhaust gases to compress the turbine and spin the intake air. This integration eliminates turbo lag, a long-standing issue with conventional turbocharging systems, resulting in automatic boost response. Additionally, e-turbos offer precise control over boost pressure, enhancing engine efficiency and power output.

Revolutionising the heavy-duty transport sector

In the heavy-duty vehicle industry, the adoption of e-turbos holds enormous potential. From freight trucks to buses, heavy-duty vehicles are major contributors to carbon emissions. Transport is the largest emitting sector of greenhouse gas ( GHG ) emissions, producing 26 % of the UK’s total emissions in 2021 ( 427 MtCO2e ). ² The biggest contributors to this were cars and taxis, which made up 52 % of the emissions from domestic transport ( 57 MtCO2e ), Heavy Goods Vehicles ( HGVs ) ( 20 % of domestic transport emissions, 21 MtCO2e ), and vans ( 17 % of emissions, 18 MtCO2e ).

Manufacturers can significantly improve fuel efficiency and emissions by including e-turbos into large transport vehicles. The benefits extend beyond climate considerations, encompassing operating efficiency and cost-effectiveness.

The use of sophisticated simulation and modeling is essential to the development of future e-turbo platforms, and this is a direct benefit of the project. In order to achieve maximum performance and emissions reduction, the project partners use cutting-edge computational tools to modify design parameters and predict system behavior. The consortia engineers were able to use simulation-driven development tools to incrementally optimize e-turbo performance across a range of operating conditions. Also, these tools play a key role in the development of next-generation propulsion technologies, including hydrogen fuel cells. By simulating difficult processes and fluid dynamics across a multitude of existing powertrains, fuel cells, hybrids, and alternative fuels, the developers can accelerate the transition to CO2-free propulsion systems. The time it takes to simulate a turbocharger heat transfer model ranges from hours on a supercomputer to minutes on a laptop.

The heavy transport industry is different, and there is no one-size-fits-all approach to decarbonising. The demands placed on propulsion systems are enormous. To thrive in this domain, e-turbos must meet strict criteria for cost performance, operating availability, design life, and reliability. Manufacturing companies are tasked with creating products that not only deliver superior performance but also withstand the demands of intense applications. Through superior materials, powerful design methodologies, and thorough testing protocols, e-turbo technology is rising to meet these challenges head-on.

The functional limits of system efficiency across several thermal propulsion powertrains are being redefined by the integration of e-turbos. Whether in standard ICE platforms, hybrid vehicles, or emerging hydrogen fuel cell technology, e-turbos offer unprecedented gains in efficiency. E-turbos optimize the air-fuel ratio and combustion dynamics to significantly reduce CO2 emissions and fuel consumption. This alternative view of system-level efficiency highlights the potential of e-turbo technology’s transformation in the transportation sector.

The UK’s e-turbo potential

The adoption of e-turbo technology in the UK offers a special opportunity to advance the local supply chain and safeguard jobs. By establishing roles in this fresh field, Project Trident has demonstrated this. As a direct result of Trident, the project partners are now looking to further invest in the creation of new related platforms, both with present customers and for the long-term development of novel fuel cell platforms, as the demand for skilled labor and specialized expertise rises.

Project Trident has demonstrated a strategic approach to nurturing a strong research, development, and manufacturing ecosystem. With this, the UK can establish itself as a world leader in ecological transportation options. Additionally, the fusion of hydrogen fuel cell platforms and e-turbo technology has a significant potential to stimulate innovation and economic growth in the UK’s mechanical sector.

The project’s conclusion allowed the project partners to reflect on a well-earned lesson learned. The project was carried out during the COVID-19 period, when innovative ways of working together had to be defined in order to remain lean in an environment, and not only had expectations been exceeded in some of the project deliverables.

The development of digital turbos marks a significant step in the decarbonization of the transportation sector. E-turbos are changing the efficiency landscape of infrared propulsion powertrains, from revolutionizing internal combustion engines to facilitating the transition to hydrogen fuel cell technology. As manufacturers embrace this revolutionary technology, they must navigate the demands of heavy-duty vehicles applications while striving for constant improvement in performance, reliability, and emissions reduction. Through simulation-driven innovation and proper investment, the UK stands poised to lead the charge towards a greener, more sustainable future in transportation.

About the Advanced Propulsion Center

The Advanced Propulsion Centre UK ( APC ) works with the UK government, the automotive industry, and academic institutions to promote the development of new technologies and facilitate the transition to zero-emission vehicles.

Since its foundation in 2013, APC has funded 264 low-carbon projects involving 492 partners, working with companies of all sizes. These initiatives will have contributed to the creation or preservation of more than 58 000 UK jobs. The technologies used in these projects are expected to save more than 410 million tons of CO2.

APC’s role in creating and advising project consortium helps projects start more swiftly and deliver more value thanks to its heavy sector expertise and cutting-edge knowledge of new propulsion technologies. In the long run, its efforts to stimulate innovation and foster collaboration are laying the groundwork for a prosperous and green English automotive industry.

The UK government made a 2019 commitment to the Automotive Transformation Fund ( ATF ) to promote the establishment of a net-zero vehicle supply chain, enabling UK-based manufacturers to serve international markets. Through the APC, ATF investments are made to support carefully significant UK capital and investments that will enable businesses in the fields of batteries, motors and drives, power electronics, fuel cells, and related supply chains to anchor their future.