By lowering energy consumption, milling systems can be optimized through mill automation to enhance operations in a variety of ways. Controlling the speed of the machine that feeds the product into the mill allows for the automation of a feed mill, which may be the key to unlocking energy efficiency and significant cost savings. Gary Kernaghan, automation manager at systems integrator Technidrive, examines how automation can enhance feed mill production energy management in this article.

Sustainability in Milling Industry

Priorities have changed in the larger milling industry, from pulp and paper to flour and grain. There is now a growing emphasis on streamlining operations, minimizing climate impact, and cutting costs rather than just concentrating on product production. This change is a reflection of the industry’s efforts to deal with the continued climate crisis and the upswing in energy prices across the country.

Consider ADM, one of the largest nutrition companies in the world. By 2035, the Strive 35 initiative aims to achieve a 90 % landfill diversion rate, reduce absolute greenhouse gas emissions by 25 %, increase energy intensity by 15 %, and increase water intensity.

The costs associated with producing feed for poultry and livestock are significantly influenced by the use of energy. In fact, according to Finning, a standard feed mill that produces 250 000 tonnes of feed annually can anticipate spending up to £750 000 per year on energy.

There are many ways to increase efficiency, including investing in more modern, energy-efficient motors, drives, and compressors as well as enhancing maintenance procedures. But, one of the most successful strategies is turning to automation.

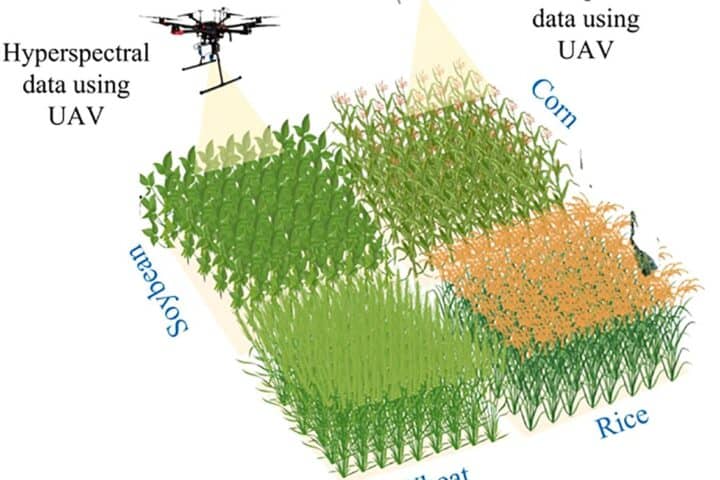

Manufacturers can ensure that there is little room for error throughout the whole processing and packaging process by automating a feed plant. Mill feeding systems need normal speed adjustments in order to process a variety of different animal feed products. The transport of materials into the mill itself, where grains, seeds, and various organic materials are ground into smaller particles or powders, is done by feeding systems.

In addition to reducing energy consumption, mills that implement automation systems that can adjust feeding speed to the desired level even help to improve sustainability practices.

A feeding system that relies on regular labor, on the other hand, may find it difficult to strike the ideal balance when adjusting feeder speed. If the speed is very slow, this difficulty frequently results in long shifts, wasted energy, and compromised feed quality if the feed rate is excessively hard. Feed manufacturers can increase throughput during each shift and reduce total running time by implementing a constantly effective feeding process that is powered by automation.  ,

Additionally, a system that constantly performs at its highest performance level saves time and enables facility managers to focus on other essential steps of the manufacturing process. This includes coordination with suppliers and distributors as well as adherence to safety regulations.

Saving energy entails lower costs.

Energy-efficient milling results in significant cost savings for businesses right away. Manufacturers can effectively reduce operating costs by reducing energy consumption, improving their general economic performance.

Automated speed control’s adaptability maximizes energy use without sacrificing operating effectiveness. This leads to reduced total plant running hours and improved product quality through ideal grinding, more advancing sustainable and economical milling practices.

Technological aspects of milling at varying speeds: variable speed drive (VSD) technology

Bespoke solutions can easily change feed mill speeds by utilizing control algorithms and precision engineering. This strategy ensures a delicate balance between energy savings and the preservation of consistency and feed quality. In order to achieve these results, powerful motor control technologies are essential.

The benefits of energy-efficient milling go beyond quick cost savings to include maintenance needs and equipment longevity. Importantly, these specialized systems offer more controlled operating conditions and wear and tear reduction, which ultimately results in longer equipment life cycles and fewer maintenance requirements.

Technidrive has created a cutting-edge automation solution to optimize feed mill operations in response to market demands. The implementation of sophisticated variable speed drive (VSD ) technology, which precisely regulates motor speed to streamline the milling feed process, is at the heart of it.

Remote Monitoring and Control

Since the installation, the throughput from the mill has increased by 29 % thanks to the integration of this solution at Kerry Agribusiness. With the help of a software interface, the automation system took the place of conventional mechanical controls, enabling seamless remote monitoring and control. Operators gain real-time insights into milling operations, eliminating the need for trial-and-error adjustments.

The system automatically adjusts the feeder’s speed, balancing energy savings and administrative effectiveness, and is enhanced by a clever algorithm. There are two advantages to using this cutting-edge solution.

First off, it reduces unwanted energy consumption by making sure the milling process is precisely calibrated, which lowers total electricity consumption and lengthens the life of the equipment. Second, throughput is increased as a result of the automation system’s significant improvement in milling efficiency.

In addition to reducing downtime, streamlined operations and remote monitoring capabilities even make it possible for quick adjustments, which ultimately results in a more cost-effective and green strategy for the milling industry.

Visit the website to find out how Technidrive’s customized solutions can transform sustainability and efficiency in the milling sector.