Brent Wilson, CEO of Galvanic Energy, looks at the development and history of petrolithium exploration.

Petrolithium: What is it?

With the development of the electric vehicle (EV), lithium has come to be referred to as “the new gasoline” and “new oil.” These descriptors, however, are only examples and are never meant to be taken literally.

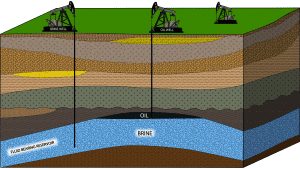

The term “petrolithium” is also not meant to refer to a fuel or petroleum and lithium mixture, which can make it unclear what lithium and ion batteries are used for. Instead of separating lithium from oil or another hydrocarbons, the term refers to the coexistence of lithium in some oilfield reservoirs or the process of extracting lithium.

Jared Lazerson, CEO and founder of MGX Minerals, a lithium mining startup company that previously promoted the chemical extraction of lithium in Alberta oilfield brines and coined the term “petrolium,” may have done so for the first time in 2016. In order to acquire mineral leases in US oilfields, Lazerson established a business under the name (PetroLithium Corporation of America) the following year. Since then, the phrase has been used to refer to various businesses that are also focused on removing lithium from North American oilfield brines, such as E3 Lithium and Standard Logic.

The discovery of gasoline

Although the term and uses for petrolithium may have only just become popular, the idea has existed for a long time. The iconic Geochemistry of Oilfield Waters ( Gene Collins, 1975 ), which noted the presence of lithium in numerous oilfield reservoirs across nine US states, was the first and most important publication on this subject.

Collins groundbreaking study was the first to use flame spectroscopic and nuclear absorption techniques to report lithium concentrations in oilfield brines.

Companies like Dow Chemical took note of Collins reporting and the anticipated future demand for lithium by the USGS. John Burba, the founder of International Battery Metals ( IBAT ), claims that in addition to Collins research, Dow was also researching lithium in oilfield brines in order to create a lithium-based battery, which other people were also working on.

The effects of Dow Chemical

Dow was in a unique position to conduct salt research during the 1970s thanks to its chemical plants and research facilities that were close to important oilfields. In one instance, Dow used bromine from the Smackover Formation to run a chemical production facility in Magnolia, Arkansas ( later acquired by Albemarle Corporation ).

Since lithium was even found in the Smackover, Dow engineers and scientists had the rare opportunity to conduct lithium battery research while also having access to a source of lithium. They just had to figure out how to extract the lithium that had been dissolved in the oilfield brine.

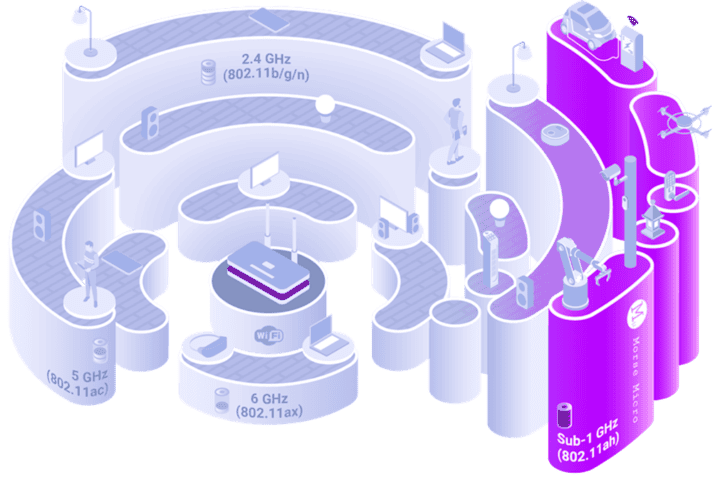

Burba claims that this is where he, Bill Bauman, Ken Klaus, John Lee, and a select group of different Dow researchers significantly contributed to the creation of an innovative ion exchange resin-based lithium extraction method. Lithium can be released with a warm water rinse after being absorbed by the resin, making the procedure pretty sophisticated.

Dow refined the process by developing a hybrid crystalline layered resin that significantly improved the ion selectivity, increasing lithium absorption while rejecting contaminants. Dow applied for an original patent in 1978, followed by further patents in 1982.

Burba and others set out to test the first version of a Direct Lithium Extraction ( DLE ) process at the Dow bromine production facility in Arkansas after it had been developed and tested in the lab.

Dow demonstrated that it was possible to economically extract lithium from oilfield brines after finishing the construction of a pilot lithium extraction plant in 1983, though the economics were n’t appropriate at the time due to reduced lithium prices and demand.

A revolution in EVs powered by lithium

DLE has seen little use since the first powerful pilot test in 1983. DLE was primarily used to improve solar evaporation processes at Salar Hombre Muerto in Argentina, despite being revived by Burba at FMC ( now Livent ) and made commercial in the late 1990s. DLE was a long-forgotten technology, with the exception of the efforts at one salar in the Andes.

However, things started to change in 2012 when Tesla Motors, a previously established EV startup, unveiled its semi-affordable Model S luxury sedan. The car was well-liked by both environmentalists and auto enthusiasts. The first-of-its-kind Gigafactory, named after the gigawatt ( one billion watts ) annual battery production potential required for the developing EV industry in North America and abroad, was announced by Tesla the following year.

Mining companies and others quickly realized the demand for lithium was going to skyrocket after the EV market took off.

According to Simon Moores, CEO of Benchmark Mineral Intelligence, a lithium mine usually takes four to seven years to build, so it was crucial to start introducing as many new opportunities as possible, including unconventional mining strategies. Thus, the petrolithium resurgence.

A breakthrough in petrolithium

Several businesses have successfully tested DLE pilot plants using oilfield brines containing economical amounts of lithium, such as the previously mentioned E3 Lithium ( Alberta ) and Standard Lithus ( Arkansas ), despite the fact that the substance has not yet reached commercialization in a petrolithium capacity. Startups are also evaluating the petrolithium potential of some oilfields, including Anson ( Utah ) and Prairie Lithewan ( Saskatchewan ).

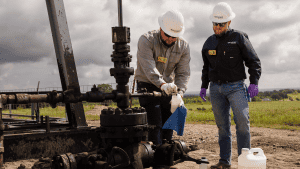

Yet Burba’s IBAT tested the same oilfield brine for the second DLE pilot plant 40 years prior, and it made a petrolithium comeback. IBAT tested the Smackover Formation in southern Arkansas during a short collaboration with Galvanic Energy and once more demonstrated that DLE has the potential to extract lithium from oilfield brines, but this time with favorable economics due to the recent increase in lithium prices.

However, the biggest breakthrough but could come from the second chapter in petrolithium. Galvanic Energy’s Smackover prospect has been acquired by ExxonMobil, and the oil supermajor plans to grow to be a significant lithium producer by 2030, producing much lithium to produce more than one million EVs annually.

ExxonMobil is on its way to upending the mining industry with its entry, as evidenced by the falling stock prices for Livent and Albemarle on the day of the company’s announcement. Also drilling, plans for a processing facility, and negotiations with EV and battery manufacturers are all currently under way.

Benefits of petrolithium

Since its inception, petrolithium has been promoted as a substitute for traditional lithium mining, which has recently come under more scrutiny from the environment.

Petrolithium offers far-reaching advantages that are better aligned with the ultimate goals of electrification than traditional mining methods. It is praised for its little surface footprint, reduced carbon emissions, and water recycling capabilities.

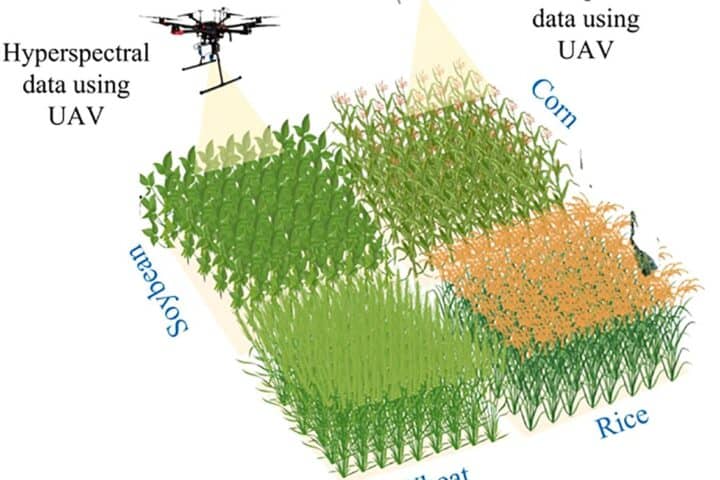

Moreover, petrolithium opens up a huge amount of undeveloped lithium in the US and Canada, lowering the country’s reliance on foreign resources and the risks to national security. North America is home to a large number of heavy oil and gas reservoirs containing lithium-enriched brines, in contrast to the salt-laced playas of the Lithium Triangle of South America or the mineral veins concentrated with lithium in the Australian Outback.

Despite not having been used in the past, petrolithium resources have long been thought about. It appears that the development of this crucial resource has suddenly occurred given the quick adoption and production of EVs, shifting economics trends, and fresh significant investments from a variety of serious parties. It will be fascinating to see how it develops over the ensuing months and years, no just in North America but also globally.