Scandium Canada Ltd. is making significant strides in developing a fully integrated scandium supply chain, beginning with mining at their Crater Lake project in Quebec and extending to various downstream applications. This project aims to meet the increasing demand for reliable scandium sources for manufacturers. CEO Guy Bourassa emphasizes the importance of creating a responsible scandium ecosystem with multiple producers and users. The company’s research focuses on discovering new markets for aluminum-scandium alloys, ensuring a steady domestic supply. Collaborating with McMaster University since 2021, Scandium Canada has advanced 3D printing of aluminum-scandium powders, overcoming previous solidification cracking issues. These breakthroughs are now being integrated into industries with shorter adoption cycles. Aluminum-scandium alloys have significant commercial applications, particularly in solar panel frames, where they enhance performance and efficiency. Scandium Canada is working with a major solar panel manufacturer to test these alloys. The solar photovoltaic industry is experiencing rapid growth, driven by renewable energy advancements and favorable government policies, with Scandium Canada committed to innovation and sustainability in advanced manufacturing and solar energy.

Scandium Canada Ltd. has made substantial progress toward establishing a completely integrated scandium supply chain, starting with mining and then moving on to various downstream applications.

The company’s flagship project, Crater Lake, located in northern Quebec, stands out as one of the few major scandium deposits worldwide.

This project aims to address manufacturers ‘ growing need for trustworthy scandium for integration into their value chains.

CEO of Scandium Canada, Guy Bourassa, stated “We firmly believe in the creation of a scandium ecosystem with many producers and users to promote a responsible scandium market.

Our findings constitute a significant step in the direction of a totally integrated scandium supply chain that will enable us to realize our Crater Lake project’s full potential.

Our research efforts help us find new markets for aluminum scandium alloys. Because potential customers have hesitant to rely on foreign sources of scandium, it is important to find new markets for aluminum scandium alloys.

We can ensure a steady and trustworthy supply of this valuable material by establishing domestic sources and integrating them into different industries, thereby promoting broader adoption and innovation.”

Advancements in 3D printing

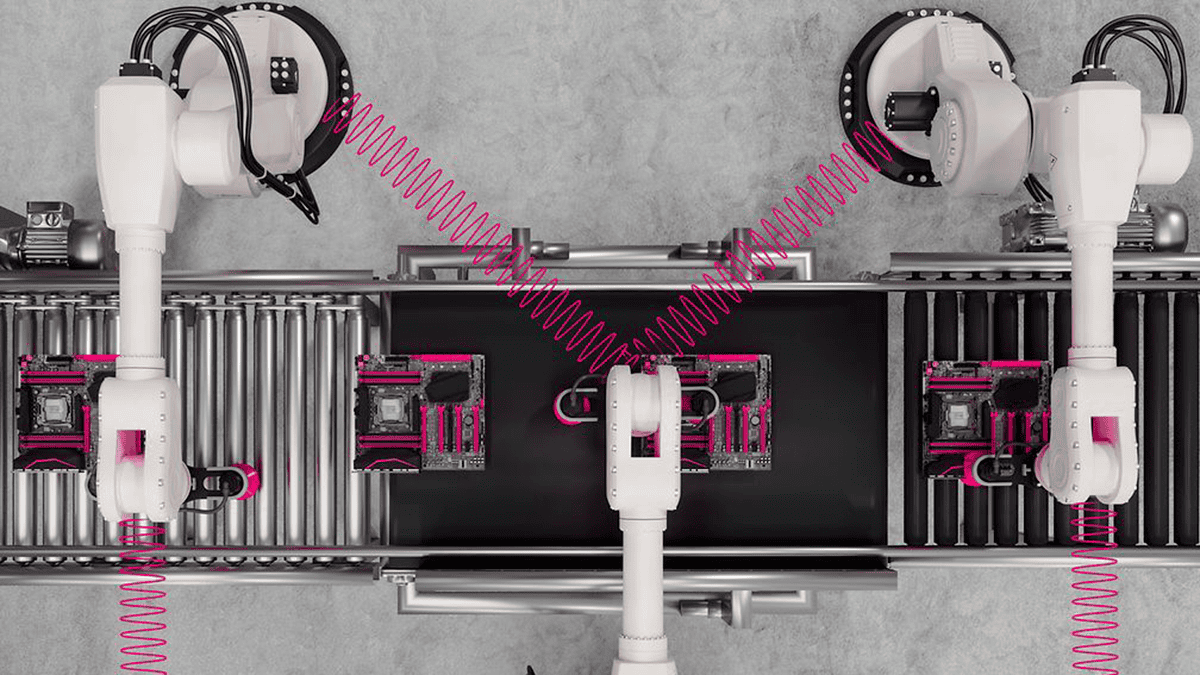

Working with McMaster University and Scandium Canada has been transforming the 3D printing of aluminum-scandium powders since 2021.

These powders, created by Scandium Canada, are unique and designed to be used to create parts that are difficult to produce using standard methods.

The company is pleased to report the powerful 3D printing of two scandium-modified aluminum alloys. Past attempts faced issues with solidification cracking, but these have now been resolved.

With possible patent applications afoot, a detailed summary of this breakthrough has been submitted to patent attorneys for review. The company is now concentrating on incorporating these findings into industries with little adoption cycles.

To test the printed products and assess their properties for several applications, active discussions with professional players are taking place.

Modern commercial applications for scandium and aluminum alloys

Aluminium-scandium alloys have a number of business applications, with one notable example being in the frames of thermal panels.

These alloys combine light and high-strength properties, making them perfect for enhancing the performance and efficiency of solar panel frames.

There is a pressing need to reduce the solar panel industry’s carbon footprint as the industry continues to expand quickly. By reducing the total weight and increasing the frame’s durability, the addition of aluminum-scandium alloys can help achieve this goal.

A big solar panel manufacturer will test the company’s current development of test alloys to extrude difficult profiles for renewable panel frames. As the process goes further, details of this agreement and the testing program will be made available to the market.

Thermal photovoltaic industry’s growth

The world solar photovoltaic industry has experienced significant year-on-year growth, fueled by the expansion of renewable energy and technological advancements.

The industry has seen considerable growth as a result of increasing environmental awareness and sympathetic government policies. This development helps to reduce greenhouse gas emissions and provide lasting energy solutions.

The solar photovoltaic industry’s growth has been further fueled by the declining costs and increased efficiency of solar panels, positioning renewable energy as a key player in the global energy landscape.

Through its included scandium supply chain, Scandium Canada continues to be committed to spur innovation and sustainability while also promoting the development of advanced manufacturing technologies and solar energy.