Retein’s biomimetic filters tackle resource extraction challenges, particularly in lithium mining and recycling, aligning with the European Union’s stringent regulations. By utilizing nature-inspired precision, these filters selectively recover lithium and water from industrial wastewater, enhancing recycling efficiency and reducing environmental impact. This technology contributes to meeting sustainability goals, especially in clean water and affordable energy, as outlined in the United Nations’ Sustainable Development Goals.

Compact and scalable, Retein’s design ensures seamless integration into existing filtration systems across various industries. By minimizing functional risks associated with battery recycling, Retein enables clients to maximize profits while reducing environmental footprint. For actors in battery recycling and mining, Retein offers partnership opportunities backed by pilot testing demonstrating improved resource recovery yields and purity. Contact Retein to explore synergies and leverage innovative solutions for a sustainable future.

EU’s Sustainable Approach: Lithium Recycling and the Battery Directive

The demand for lithium, essential for energy storage systems such as lithium-ion batteries, is projected to exceed supply by 2025.

Now, lithium mining is largely conducted outside of Europe, in regions such as Chile, Australia, and China, intensifying Europe’s dependence on outside sources.

Additionally, this reliance raises political issues for Europe because recycling the lithium that is now present in used lithium-ion batteries is the only way to achieve some degree of lithium self-sufficient.

To address these challenges, the European Union has introduced strict regulations under its new battery directive, mandating large recycling targets.

By 2025, 65% of lithium in batteries must be recycled within the EU, escalating to 80 % by 2031. By encouraging round resource handling, this regulation aims to lower lithium dependence and lessen the effects of lithium mining on the environment.

Revolutionizing Recycling: Retein Biomimetic Filters for Sustainable Lithium Recovery

The advancement of superior recycling techniques has been fueled by the desire to be sustainable.

Traditional recycling techniques frequently succeed in recovering high-value materials like cobalt or copper from used lithium-ion batteries but fall short of recovering sufficient amounts of extremely in-demand materials like lithium.

This growing demand is causing the development of novel technologies that make lithium more effectively and selectively recovered.

Additionally, tale technologies can provide more commercially viable recycling methods than the ones available today.

Solution for Sustainable Resource Recovery

Retein creates industrial-grade filters that make use of nature’s exceptional precision and effectiveness in recovering water-borne resources for reuse.

These filters are based on mitochondrial processes and use specific proteins that can transport certain resources like lithium and water with little energy.

This technique significantly improves recycling efficiency and reduces environmental impact by allowing for both the careful recovery of lithium from used batteries and the purification of water from industrial wastewater and process streams.

Retein’s technology works by embracing proteins that transport the desired resource within a cell-like environment. Depending on the resource targeted, various proteins can be used to transport that resource exclusively.

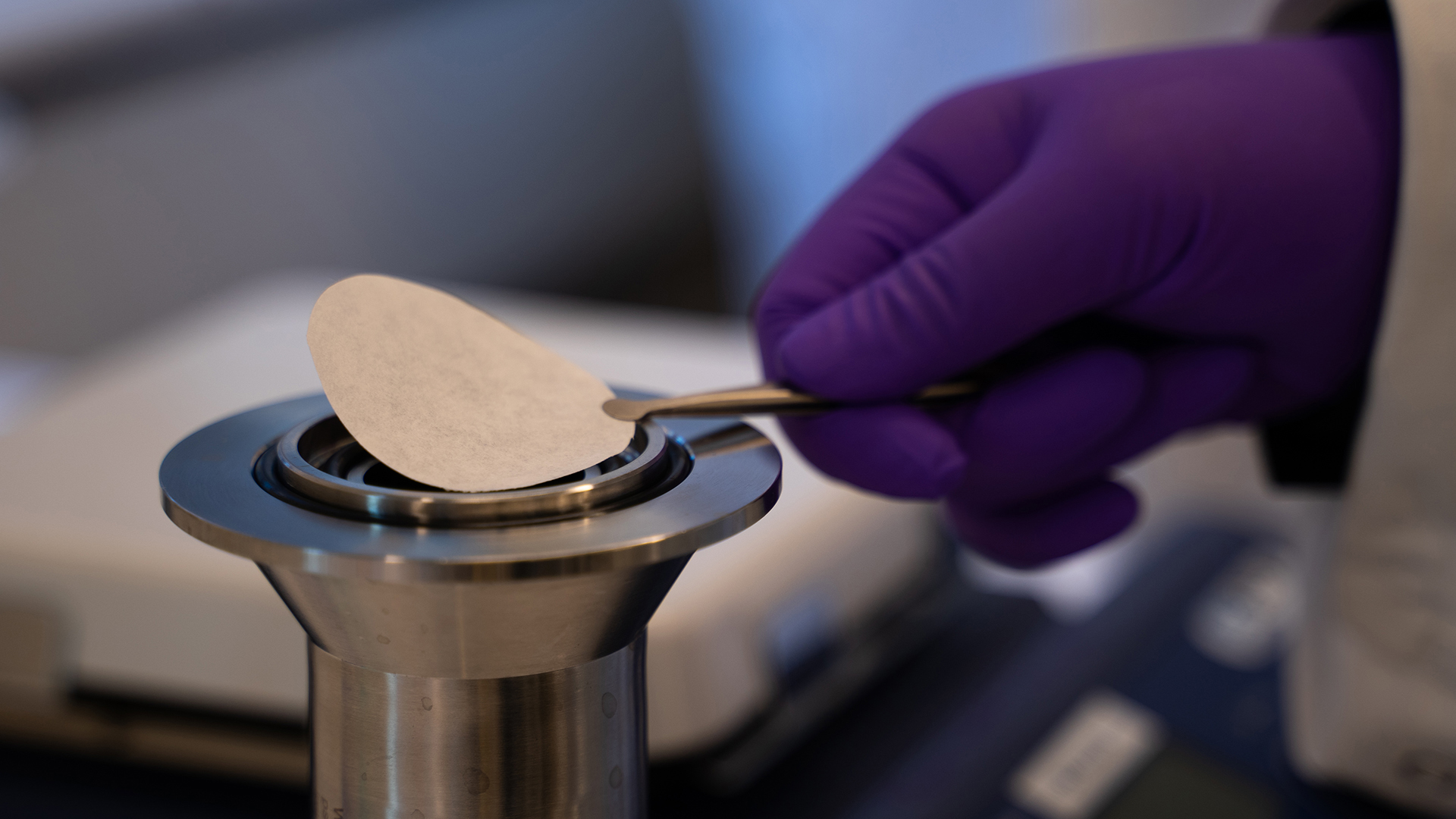

The cell-like structure is then stabilized to become capsules that are more resistant to outside forces like pressure and concentration. To create a very effective filtering membrane, the stabilized capsules are incorporated into a polymer matrix. The precise resource is shortened through the often densely packed membrane material because capsules are incorporated into the polymer matrix.

Nature-Inspired Filtration: Retein’s Solution for Sustainable Resource Recovery

The filter material has a special nature-inspired feel to it, and it is packaged into standard filtration modules that are used today in various industries. Retein’s filters are therefore suitable for use in existing installations without significant structural changes while also meeting the requirements of greenfield projects involving electrification.

Retein’s solution’s compact design makes it simple to scale up to meet growing demand and adaptability to various battery sizes or lithium source types.

With less sensitivity to changes in the process water composition, the increased flexibility with respect to source types allows for refined metal extraction and refinement. This is attributed to the special abilities that nature’s best resource recovery possesses.

Retein offers filters that open new avenues for recovering significant water and resources from water mixtures, in contrast to commercial filters that are currently available.

The very precise separation will make spiral processing more cost- and-effective. The most recent state-of-the-art separation process divides through one or at most two atomic characteristics.

In contrast, channel proteins have been tuned by nature to separate on no fewer than four characteristics: size, charge, hydrophobicity, and precise covalent interactions.

Retein’s filters so have the ability to deliver outstanding performance when recovering lithium and other water-borne resources with the least amount of energy.

Retein’s Contribution to Sustainable Development Goals: Enhancing Resource Recovery for a Greener Future

The United Nations ‘ Sustainable Development Goals ( SDGs ) align with the goals that are set in the SDGs. Responsibility for managing water and energy is becoming more and more of a social and economic license-to-operate issue, and more stringent environmental laws are being implemented.

Retein’s efforts in metal and water recovery are particularly geared towards improvements in SDG 6 ( Clean Water and Sanitation ) and SDG 7 ( Affordable and Clean Energy ).

Retein helps clients increase their profits while simultaneously reducing their risks through a solution that maximizes yield while minimising bad impact, just like nature does, by improving resource recovery yields and quality while reducing waste.

This use of resources that are now present in the process even makes it possible for battery recyclers and miners to capitalize on higher profit margins and a more cost-effective offering to their customers.

Through pilot testing in a variety of settings, Retein is demonstrating improvements in lithium and water recovery yield and purity as well as reduced administrative costs and risks.