Helium demand plays a critical role in the semiconductor manufacturing industry, where its unique cooling properties are essential for producing advanced chips. As semiconductor technologies evolve—driven by initiatives like the US Chips Act and EU Chips Act—helium demand is expected to increase fivefold by 2035, according to IDTechEx. Helium’s high thermal conductivity and inert nature make it indispensable for cooling during chip production, especially as semiconductor nodes shrink. However, helium supply has faced significant shortages due to geopolitical tensions and plant outages, causing price fluctuations and supply chain issues. While helium reserves could theoretically last 250 years, surging demand from industries like energy vehicles, 5G telecommunications, and AI could shorten this timeline dramatically. To combat helium supply challenges, the semiconductor industry is exploring helium recycling, a practice already adopted in sectors like cryogenics and fiber optics. Though still in its early stages, helium reclamation could offer a sustainable solution, ensuring semiconductor manufacturers can meet growing demand while mitigating supply risks. As the industry faces mounting helium shortages, innovative approaches to recycling and resource management will be essential for balancing growth and sustainability in the future of semiconductor manufacturing.

The semiconductor manufacturing industry, a cornerstone of modern technology, relies greatly on helium due to its unique properties.

Helium’s role in this sector is essential, especially in the context of crystal cooling, where its frozen abilities are unmatched. The demand for helium is expected to skyrocke as semiconductor manufacturing is on track to experience major growth, thanks to initiatives like the US Chips Act and EU Chips Act.

Helium demand in semiconductor manufacturing is anticipated to grow fivefold by 2035, according to a new report from IDTechEx. Helium’s bounded nature, however, raises questions about the viability of this important industry.

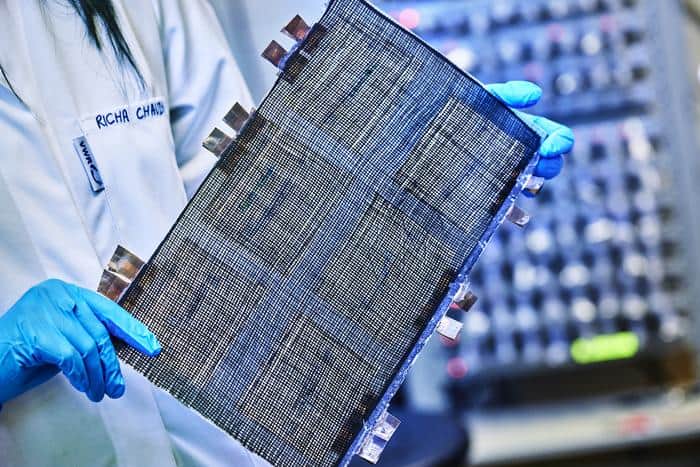

Helium’s crucial role in semiconductor manufacturing

Helium is essential in various stages of semiconductor manufacturing, mainly because of its high thermal conductivity and inert characteristics.

Its ability to quickly cool over chips during the production process makes it unique, especially as semiconductor nodes shrink and use it more effectively.

The need for improved infrared management grows more important as the semiconductor industry pushes the boundaries of technology with advances in AI, quantum computing, and mechanical automation.

Helium plays a significant role in this, making sure chips are produced in the most efficient manner without risk of overheating.

Helium demand is expected to grow significantly as energy vehicles and 5G telecommunications become more popular.

The challenges of helium supply shortages

Despite its significance, the helium market has endured unrelenting supply shortages for the past 20 years.

These shortages, exacerbated by political tensions, plant outages, and maintenance issues, have led to price fluctuations and supply chain disruptions.

Semiconductor manufacturers, in response, have had to adjust production rates during periods of helium scarcity to manage costs and resource availability.

Although increased helium production is expected, especially from countries like Qatar and Russia, supply security remains uncertain.

These areas frequently experience political instability, which could put additional strain on the availability of helium.

According to the United States Geological Survey, there are approximately 40 billion cubic meters of complete helium reserves worldwide.

At the current rate of production, this could last nearly 250 years. However, with rising helium demand in semiconductor manufacturing, this timeline could be shortened tremendously.

Exploring lasting solutions and helium recycling

Sustainability is quickly becoming a top issue for the semiconductor manufacturing industry because of the fixed nature of helium.

Another sectors, such as fibre optics and cryogenics, have already begun adopting helium recycling methods to mitigate supply challenges.

The need to manage rising helium costs and uncertain supply chains is driving the growing trend of helium reclamation in industries like aerospace and mechanical leak testing, according to IDTechEx’s report.

In semiconductor manufacturing, helium recycling is still in its infancy. The adoption of reclamation technologies is possible to increase as the industry struggles with supply shortages and the rising cost of specialty gases.

Helium recycling systems could be a lasting solution for semiconductor manufacturing plants to meet growing helium demand while reducing the impact of upcoming supply disruptions.

The road back: Balancing growth and sustainability

The industry must prepare for possible shortages in the future, even though expansions in helium production may ease some supply issues.

With helium demand projected to skyrocket by 2035, semiconductor manufacturers must explore other strategies, including the implementation of helium recycling technologies, to ensure long-term sustainability.

Industries will need to innovate and adapt as helium demand rises in order to ensure a secure, sustainable future for semiconductor manufacturing.