microSHIFT, in collaboration with the Taiwan Smart Electric Bicycle Association (TSEBA), has taken significant strides in 5G smart manufacturing. During a recent event at the Taichung GIS Convention Centre, microSHIFT unveiled its successful implementation of 5G smart production lines. The partnership has been bolstered by support from FlexLink, Inventec, and NewWave, along with the Ministry of Digital Affairs (moda). This initiative falls under Taiwan’s 5G Modern Application Project and highlights the transformative potential of 5G private networks in the manufacturing sector.

With the integration of IoT, MES, and advanced AI-driven solutions like real-time equipment health diagnostics, microSHIFT is enhancing the efficiency of its bicycle gear system production. By leveraging the vast bandwidth and multi-connectivity of 5G, microSHIFT has reduced delivery lead times and improved order fulfillment and CNC machine utilization. The impact of 5G and AI technology on smart manufacturing is profound, allowing businesses to optimize production processes, reduce labor costs, and boost revenue. This showcases microSHIFT’s commitment to advancing 5G smart manufacturing, improving operational efficiency, and setting a benchmark in Taiwan’s bicycle industry.

microSHIFT Partners with TSEBA and Industry Leaders to Accelerate 5G Smart Production in Taiwan

microSHIFT, in partnership with the Taiwan Smart Electric Bicycle Association (TSEBA), recently hosted a presentation on the 5G smart production lines they’d deployed, at the Taichung GIS Convention Centre. The event saw participation from key industry players, including FlexLink, Inventec, and NewWave, alongside various bicycle supply chain manufacturers from Central Taiwan.

The Ministry of Digital Affairs (moda) has been actively working with public organizations since 2023 to advance the development and use of 5G private networks across a range of sectors. Through scientific innovation, the aim is to increase business competitiveness.

Moda supports these efforts by implementing important policies, fostering industry-academia collaboration, and providing financial and technical assistance. This comprehensive approach facilitates the swift integration of 5G technology, accelerating industry upgrades and transformation. Under the guidance of the Digital Industries Administration, microSHIFT has teamed up with FlexLink, Inventec, and NewWave to explore 5G applications through the’ 5G Modern Application Project,’ speeding up the journey towards intelligent manufacturing.

How 5G and AI Are Revolutionizing Manufacturing: Insights from TSEBA and microSHIFT’s Smart Production Model

The combination of 5G and AI has the potential to have a revolutionary impact on the manufacturing industry, enabling technological advancement and innovation.

“5G bright factories can address the issue of labour shortages in manufacturing. The online and offline included production model enables the instant collection of numerous production data in real time. This enables versatile production with limited production and a variety of options, and it makes use of AI for analysis to improve production efficiency and yield, according to Thompson Su, TSEBA Secretary General. It achieves cost and performance optimization for” bright factories,” which can then lead to an artificial production platform and manufacturing base. The modern application project for the 5G intelligent production line is used as a model for microSHIFT’s completion. We hope that all association members can upgrade effectively, enhance their competitiveness, and continue to thrive, becoming the best exceptional enterprises in Taiwan”.

Established 25 years ago, microSHIFT is a manufacturer of bicycle gear systems, serving main markets in North America, Europe, Central and South America, and Asia. The company’s clients include recognized bicycle brands such as Decathlon, Giant, and Merida. MicroSHIFT has manufacturing facilities in China, a research and development center in Taiwan, and a brand and market development center in the United States.

Smart manufacturing enables versatile production, optimises efficiency, and enhances business resilience.

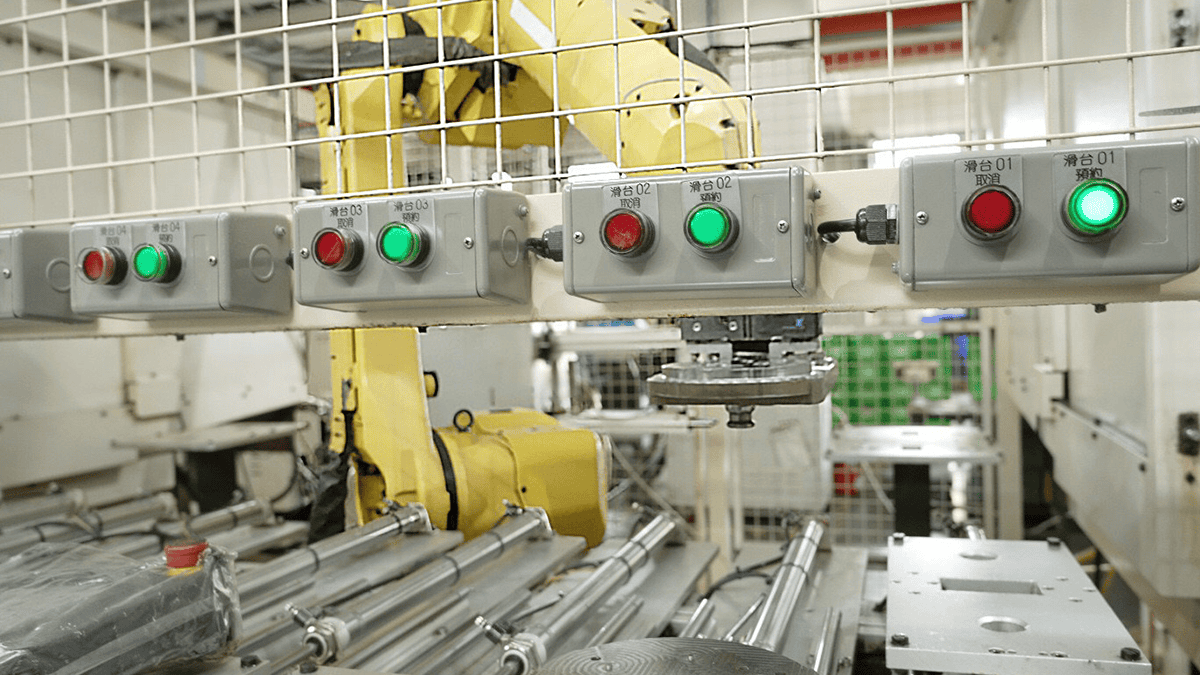

According to William Chen, CEO of microSHIFT,” we saw an opportunity to start our modern transformation project. We looked at the trends in 5G smart manufacturing and AI. MicroSHIFT has successfully established a 5G bright production line for bicycle gear systems and is the first private company to take part in the government’s 5G Dedicated Network Innovative Application Diffusion Project. We’ve already deployed 5G dedicated network equipment, including applications like the Manufacturing Execution System (MES), the Internet of Things (IoT), advanced planning and scheduling (APS), and real-time equipment health prediction and diagnostics. Also, we have addressed 5G network security planning and safety verification.

Chen went into detail about how these technologies are being used in the CNC processing area, where two tiny base stations and 5G technology have been put in place. With support from Inventec, 33 CNC and cheap injection machines have been networked, and equipment health prediction diagnostics have been implemented. Leveraging the huge bandwidth, reduced overhead, and multi-connectivity features of the 5G private network, real-time data is captured, and a tool wear database is established.

5G-Powered AI Forecasting Boosts Production Efficiency and Cuts Costs for microSHIFT’s Smart Manufacturing

AI-trained forecast models issue warnings before tool failures, reducing operating inefficiencies and preventing faulty production. However, the smart reporting system, powered by 5G, significantly reduces the time previously spent on paper-based processes and lowers error rates. The returned information is integrated with Siemens ‘ bright scheduling system, OPCENTER, enabling real-time, flexible adjustments to work orders and improving order fulfilment rates.

By capitalising on the broad bandwidth, reduced overhead, and many connections offered by the 5G private network, microSHIFT has implemented different applications such as MES, IoT, APS, and real-time equipment health diagnostics. These improvements have improved management and production effectiveness.

Delivery lead times have been cut by 15 days, order fulfillment has increased by 10%, material availability has improved by 10%, and CNC machine utilisation has increased by 15%. The initiative is anticipated to substantially lower labor costs, improve forecasts for equipment maintenance, and increase overall revenue and profit margins for products.