Programmable integrated circuitry is composed by tiny electric parts that have been designed so that a designer can set them up to carry out particular tasks. The complexity of these programmable logic devices can range from a few hundred to tens of thousands of gates that are similar. This article will discuss the various types of programmable integrated circuits (ICs), their primary functionality, similarities, and differences, as well as the advantages and disadvantages of each type and the fields in which they are used.

Evolution of Programmable Integrated Circuitry: From Microcontrollers to Programmable Analog ICs

Engineers have worked to make their circuits as adaptable as possible to save time, money, and resources ever since the invention of electronics. This task grew more significant than previously as a result of the development of ICs created by Robert Noyce at Fairchild Semiconductor in 1959. The more applications your IC can handle, the more pieces you can offer customers, and the greater the revenue your company generates. As a result, the internal IC design was fairly straightforward. It could be used in a number of circuits in this way, but doing so required the use of numerous physical components. frequently highlighting the benefit of miniaturization. All of that changed when Gary Boone and Michael Cochran, two engineers at Texas Instruments, created the microcontroller (MCU) in 1971. Thanks to its programmability, one tiny chip can now be used in a recently unthinkable range of applications. A short while later, a growing number of customizable IC types started to appear, each with its own special uses and functions.

- An embedded system’s MCU (Microcontroller) is a small integrated circuit that is used to control specialized operations. A typical microcontroller consists of a single chip that houses the processor, memory, and input/output (I/O) peripherals.

- Infineon’s PSoC (programmable system on a chip) family of integrated microcontroller circuits. These chips have a CPU core and mixed-signal arrays of included analog and digital peripherals that can be configured.

- A matrix of configurable logic blocks (CLBs) connected via programmable interconnects serves as the foundation for semiconductor devices known as FPGAs (field programmingable gate arrays). After manufacturing, FPGAs can be reprogrammed to meet specific application or functionality requirements.

- The CPLD ( complex programmable logic device) combines the architectural features of both Programmable Array Logic (PAL) and FPGA to create a complex logic structure. A macrocell, which houses logic implementing discontinuous ordinary form expressions and more specialized logic operations, is the primary building block of the CPLD.

- Integrated circuits with configurable analog functionality known as programmable analog ICs (PACS) let users customize and modify analog circuitry based on particular application requirements. By enabling the programming or reconfiguration of several analog functions, such as amplifiers, filters, voltage references, and another analog components, PAsICs offer flexibility in analog signal processing. These ICs offer versatility and adaptability in a variety of electronic systems and applications because they normally allow for programming changes to analog parameters rather than physical ones.

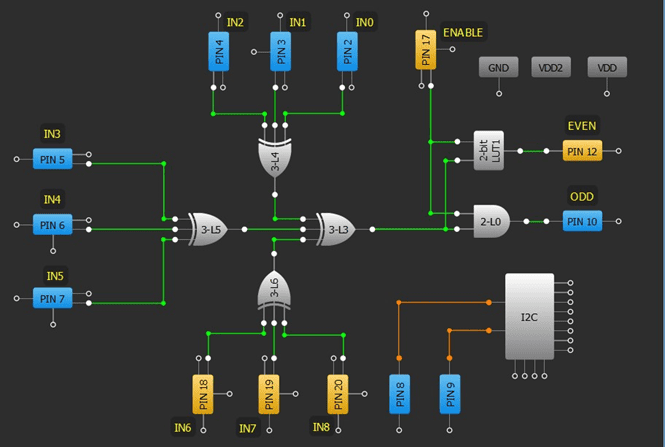

- GreenPAK customizable mixed-signal matrices offer a small, low-power component for frequently used mingled signal functions. By configuring the interconnect logic, the IO pins, and the macrocells in the One Time Programmable (OTP) Non-Volatile Memory (NVM), the circuit design can be produced. These incredibly adaptable gadgets make it possible to design a wide range of mixed-signal functions within an extremely compact and low-power single-integrated circuit. With the rise in popularity of cell phones, telecommunications, convenient electronics, and cars with electronics and digital sensors, their use has skyrocketed.

Comparison of ProgrammableICs

The advantages and disadvantages of each type are listed in the table below.

Table 1. Comparison of programable ICs

| Criteria | Microcontrollers (MCUs ) | PSoCs | FPGAs | CPLDs | PAsICs | Mixed-signal programmable Matrices ( GreenPAKs ) |

| Advantages | ||||||

| Cost-effectiveness | ✔️ | ✔️ | ||||

| lower energy use | ✔️ | ✔️ | ✔️ | |||

| integrated accessories | ✔️ | ✔️ | ✔️ | |||

| integration of mingled signals | ✔️ | ✔️ | ✔️ | |||

| higher degree of customisability | ✔️ | ✔️ | ✔️ | ✔️ | ||

| processing in parallel | ✔️ | ✔️ | ||||

| Flexibility | ✔️ | ✔️ | ||||

| Customisability | ✔️ | ✔️ | ✔️ | ✔️ | ||

| lower energy use (in CPLDs) | ✔️ | ✔️ | ||||

| Personalized analog functionality | ✔️ | ✔️ | ||||

| Integration | ✔️ | ✔️ | ✔️ | ✔️ | ||

| Reconfigurability | ✔️ | ✔️ | ✔️ | ✔️ | ||

| programmability without code | ✔️ | ✔️ | ||||

| Disadvantages | ||||||

| a small processing capacity | ✔️ | ✔️ | ✔️ | |||

| limited adaptability | ✔️ | ✔️ | ✔️ | |||

| sluggish horizontal processing | ✔️ | ✔️ | ||||

| Complexity | ✔️ | ✔️ | ||||

| energy use | ✔️ | ✔️ | ||||

| higher price | ✔️ | |||||

| Specificity | ✔️ | ✔️ | ||||

| intricate design | ✔️ | ✔️ | ||||

| requires knowledge of programming | ✔️ | ✔️ | ✔️ | ✔️ |

As we can see, the table declares that mixed-signal customizable Matrices are unquestionably winners. They cannot, but, compete on an equal footing with FPGAs, for example, and are not the solution for every circuit design. However, the second best option might be this large IC family. A GreenPAK family of affordable NVM programmable devices is an illustration of one of these IC types.

Unlocking Efficiency with GreenPAK: Versatile Mixed-Signal Integration for IoT Applications

GreenPAK’s integrate analog components like operational amplifiers (OPAMPs) analog comparators (ACMPs), analog-to-digital converters(ADCs); digital to-analogue converter (DACs; and programmable interconnects. They also include highly configurable digital logic blocks like clocks, LUT, DFF, counter/delays, memory, etc. GreenPAKs typically function as PSoCs without a microcontroller core, though some do have modern logic blocks that can perform basic math.

These tools enable the processing of mixed-signal inputs by enabling users to configure both analog and digital functions. They are capable of mixed-signal interfacing, electronic signal processing, and analog signal conditioning tasks. Additionally, working on a new design does n’t take hours, sometimes days, learning new software documentation, or, in the worst case scenario, an entire programming language; instead, it only takes minutes thanks to the software’s high level of intuitiveness. Since the GreenPAK ICs are zero-code programming devices, configuring them does n’t require the use of any programming language.

Check out the GreenPAK Cookbook as well. The purpose of this document is to highlight applications for a GreenPAK in the work of electronics design engineers. To assist designers in using GreenPAK on their own, it outlines various techniques and offers comprehensive applications.

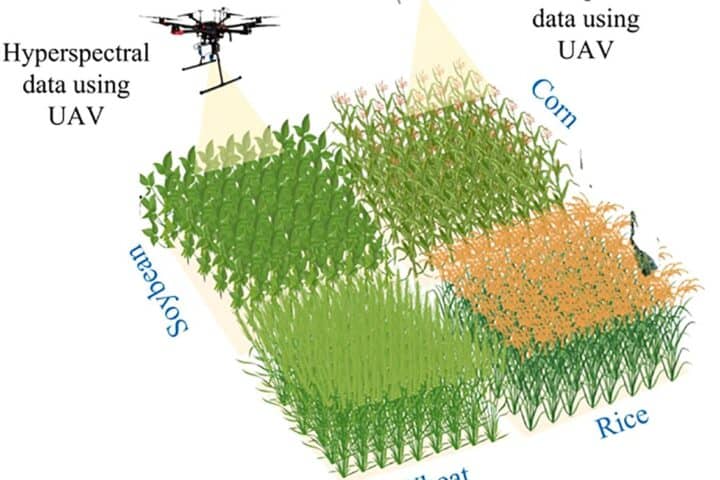

Applications for GreenPAKs can be found in communication systems, sensor interfaces, data acquisition devices, and music processing equipment where both analog and digital signals must be processed. They are useful in applications that call for accurate real-time signal conversion, filtering, and manipulation. You can access the complete library of real-world applications created with GreenPAK at the Renesas website.

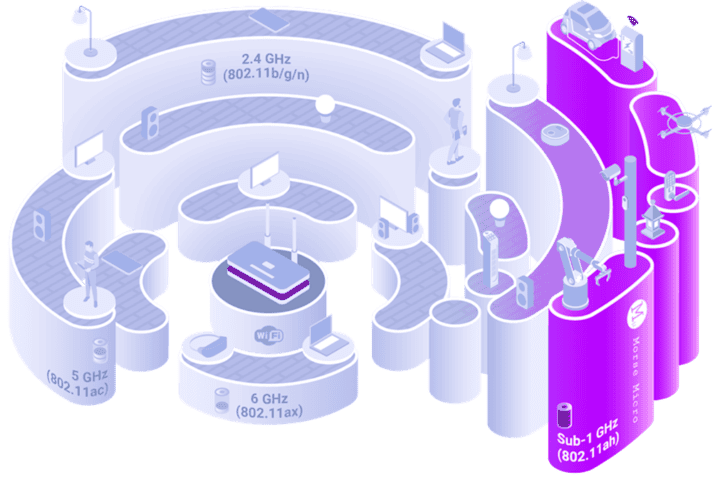

These mixed-signal customizable matrices provide a complete solution for applications that call for complex processing capabilities for both signal types, serving as an intermediary between the analog and digital worlds. They are ideal for a variety of applications where detailed control over mixed-signal processing is essential, such as IoT, due to their flexibility and configurability.

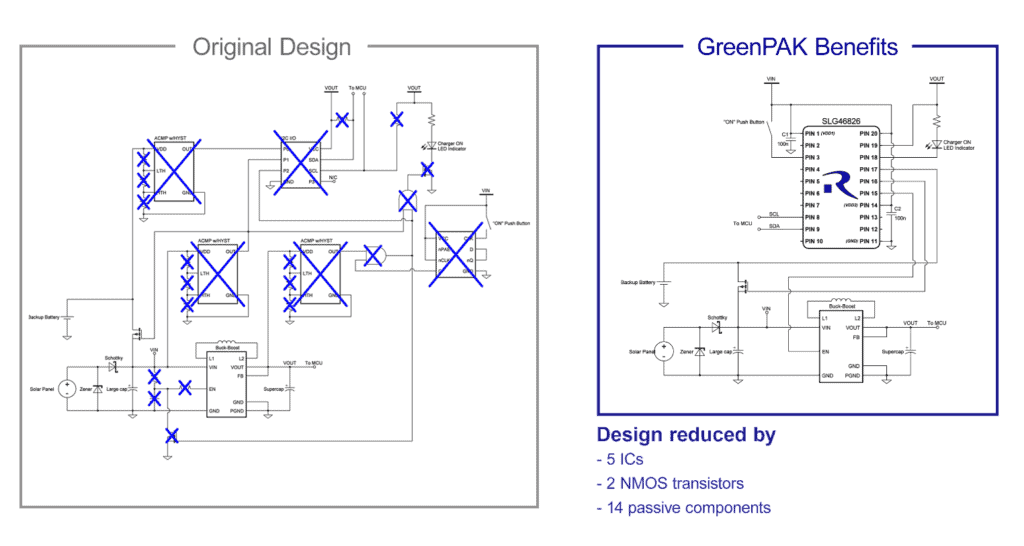

Each customizable IC type listed in Table 1 has its own benefits, distinctive features, and applications. However, the extraordinary versatility and cost-effectiveness of GreenPAKs are what make them special. This means that a single device family can typically replace all of the ICs mentioned above and meet about all design requirements. It is both power and Motherboard space efficient at the same time. consuming nano amperes in a small STQFN package while they are empty. This level of adaptability is frequently employed to significantly shorten PCB size, BOM price, and design time. See the figure below for an illustration of design optimization.

Circuit design engineers are frequently driven by a combination of laziness and ignorance of the IC market rather than by cost, PCB space, or existing consumption effectiveness when designing their devices or parts of them. This makes sense given that there are numerous IC companies that provide a wide range of components for every solution. To learn all of them would take a lifetime. In order to avoid learning fresh documentation for any novel IC, the typical engineer, for instance, may choose one MCU or family of MUCs and incorporate it into every design. Additionally, each business has its own software and occasionally perhaps a programming language. Designs that are ineffective and excessive, like using an MCU to blink an LED, may result from this. Even though this might justify a reduction in man-hours, it puts the competition at an entire disadvantage. The GreenPAK family is extremely useful in this situation, particularly in Internet of Things (IoT) applications.

Meeting IoT Demands with GreenPAK: Efficiency, Integration, and Reliability

To enable effective and dependable functionality within devices, Integrated Circuits used in IoT must satisfy particular requirements. The variety of IoT applications, which can range from tiny sensors to sophisticated data processing systems, shapes these requirements. These are some important IoT IC requirements and how GreenPAKs meet them:

- lower energy use: IoT devices are often battery-powered or need to operate on low power to extend their lifespan. All the ICs within the GreenPAK family are very energy-efficient, enabling devices to operate for extended periods without frequent battery replacements. Typical idle current consumption is less than 1 µA.

- IoT devices are frequently small and lightweight. The smallest GreenPAK package, which is 1.0 x 1.2 X 0. 55 mm in size, allows it to easily fit inside the small space of any IoT device. All of these packages are made of small TQFN and MSTqFN.

- Low cost: Mass deployment of devices is a common feature of IoT applications. To keep the total cost of IoT devices low, cost-effective ICs are crucial. GreenPAKs are available for purchase at$ 0.18.

- IoT devices are susceptible to security threats due to their security features. GreenPAKs are difficult to hack into because they lack Laptop cores.

- Integration of sensors and actuators: For data collection and control, IoT devices frequently need sensors ( e .g., temperature, humidity, motion ), as well as motors and relays. ICs with a variety of input and output interfaces are part of the Broad GreenPAK family. Among the many, there are analog comparators, OPAMPs, and ADCs on the input and DACs and high-power complete half-bridges for the output.

- Running power: ICs should offer enough processing power to handle data processing tasks, particularly for edge computing and real-time analytics, depending on the complexity of the IoT application. GreenPAKs include a wake and sleep timer, which can lower both their power consumption and that of other ICs in the IoT device.

- Low overhead: Some IoT applications, especially those that involve real-time monitoring or control, call for low-latency communication. The signal propagation delays on GreenPAKs used in these applications are just tens of nanoseconds.

- GreenPAKs are made to integrate easily with other components and protocols, ensuring interoperability and compatibility within the IoT ecosystem.

- The GreenPAKs ecosystem enables user-friendly development tools and zero-code software with a very straightforward GUI that makes it possible to create custom ICs quickly, speeds up the creation of IoT applications, and shortens the time it takes to get to market.

- IoT devices can be used in a variety of environments, including the outdoors and in the workplace. ICs in the GreenPAK family are made to withstand climate elements like temperature changes, humidity, and vibration. including mechanical AEC- Q100 qualified ICs and those with an extended operating temperature range of -40°C to 125°F.

GreenPAKs used in IoT applications can enable dependable, energy-efficient, and stable connectivity and data processing thanks to the fulfillment of these requirements, making them ideal for but not just the wide range of devices and deployments.

Conclusion

Renesas Electronics Corporation’s GreenPAK IC family is a standout option for handheld, home appliances, mechanical, and various end applications in addition to IoT. On the Renesas website, there is a fantastic selection of application notes for additional information and advice.