Nickel-based superalloys are the industry leaders in materials engineering because they exhibit unmatched resilience in high-temperature environments, making them essential for a wide range of commercial applications.

Nickel stands out as the stalwart, offering robustness and steadfastness, when normal materials like steel or titanium alloys respond to extreme conditions.

Their unique characteristics are greatly influenced by particular alloying components that improve their structural prowess.

This article explores the additive manufacturing ( AM ) field in relation to these sturdy nickel-based superalloys and provides a thorough explanation of their fabrication procedures.

innovative mechanical ideas

It is essential to comprehend the metallurgy of nickel-based superalloys in antioxidant manufacturing.

These alloys maintain their strength yet at temperatures higher than 540°C, distinguishing them from their conventional counterparts and earning the moniker” superalloy.”

For enduring great stress at high temperatures, the incorporation of alloying elements improves both their mechanical properties and histological stability.

Intense interactions during the fusion-based AM process are revealed by detailed mechanical analysis, which causes complex phase transformations within parts as a result of non-equilibrium solidification. This investigation provides insightful knowledge about managing these interactions to produce the best results.

Nickel-based superalloys ‘ performance is significantly influenced by the microstructural stability of these materials. The resistance of an alloy to deformation and cracking at higher temperatures can be affected by grain boundary segregation, in which alloying elements concentrate along grain boundaries.

It becomes crucial to keep an eye on any microhardness variations brought on by changes in processing or composition.

Infrared behavior is also crucial. Several thermal cycles are induced by the repeated heating, melting, and cooling during fusion-based AM, considerably influencing final properties like hardness and tensile strength.

Understanding how these cycles impact the microstructure helps to foresee potential flaws or weaknesses before they appear, increasing AM practices ‘ overall effectiveness and quality control.

incorporating antioxidant manufacturing technologies based on fusion

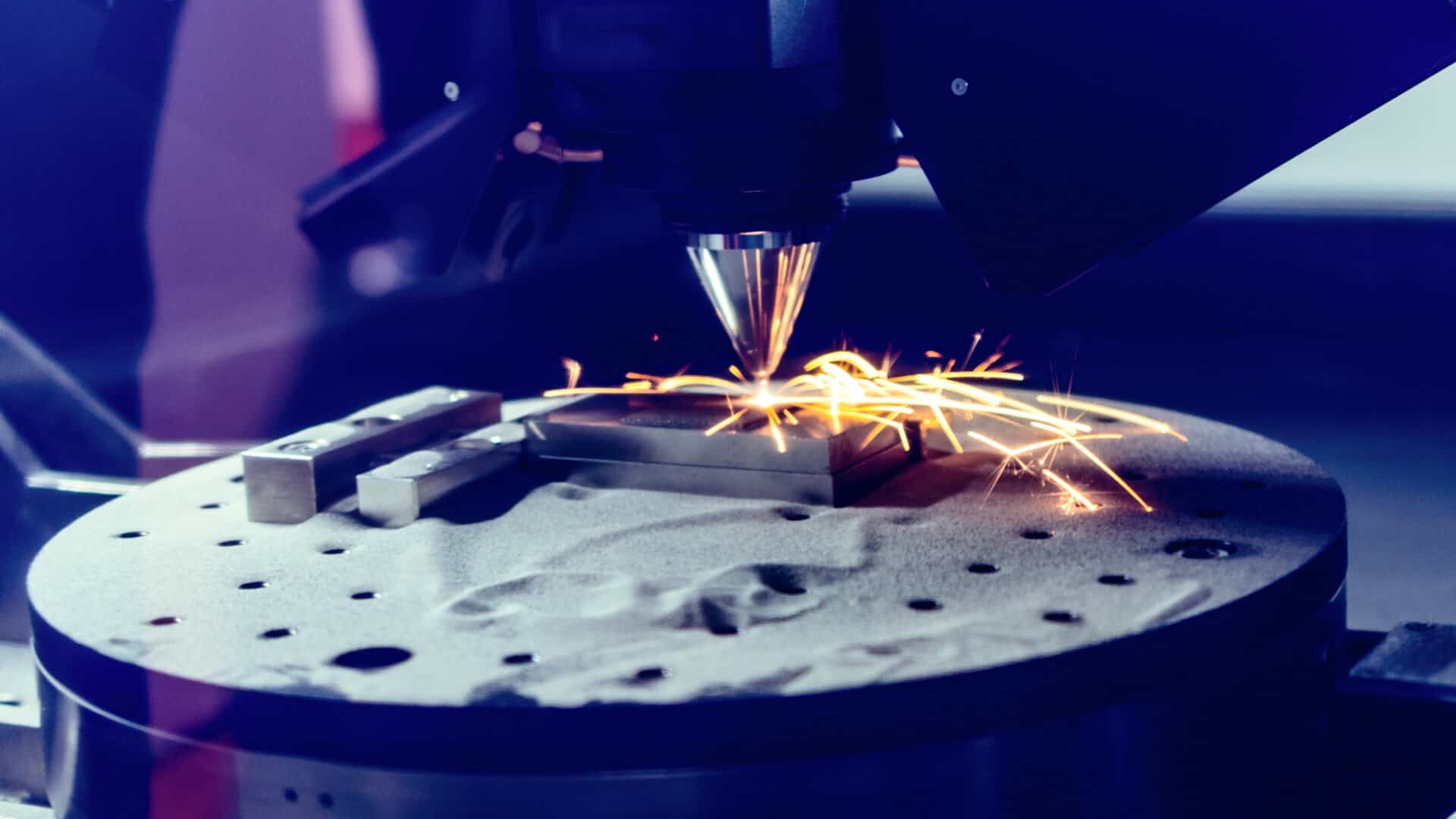

Laser or electron beams are used in Fusion-based AM technologies to cause fast solidification, which greatly improves alloy properties.

The microstructure and performance characteristics of the resulting feedstock, which is usually in powder or wire form, are influenced. Specific process parameters and microstructure analysis are included in strict quality control measures, which reveal possible improvements during production runs.

Nickel-based superalloys are further refined by post-processing techniques, which reduce porosity, improve mechanical properties, and incorporate surface finish.

Processability is considerably influenced by the characteristics of powders, including variables like morphology and size distribution. Excellently flowable powders enable effective melt flow into pores, improving total product quality.

Compatibility of alloys: Important factors

In fusion-based AM, alloy compatibility plays a crucial role. A complete weldability analysis is required due to the non-equilibrium solidification process and intricate melt flow that the parts experience.

In order to maintain fundamental integrity, it is crucial to comprehend phase transformations within these superalloys. Material bonding and performance under service conditions are optimized by efficient management of thermal history and strategies for controlling phase transformations.

figuring out structural characteristics

According to their non-uniform microstructure following AM processing, evaluating the mechanical properties of nickel-based superalloys proves difficult.

Comprehensive characterisation is necessary for deformable properties, which are influenced by load orientation in relation to the build direction.

For a comprehensive evaluation, conventional testing methods must be supplemented by cutting-edge methods like modern image correlation and thermo-mechanical fatigue.

Simulating and modeling: Fine-tuning

In order to understand the complexity of AM processes, sophisticated simulation techniques are essential. More precise predictions are made possible by taking into account transient temperature variations, Marangoni convection, and heat source movement.

These simulations provide knowledge of the melodic effects on microstructure and provide direction for alloy design for superalloys made of AM-processed nickel.

creating alloys for the future

Composition, histological control, process optimization, and surface finish must all be taken into account when designing alloys for AM-processed nickel-based superalloys.

These included elements improve structural and fabrication capabilities, opening the door for high-performance applications. The huge potential of AM technology is expected to be explored further as a result of ongoing developments in this area.

identifying potential research frontiers

Future research in this area focuses on improving process control, reducing flaws, developing new scan techniques, optimizing beam profiles, and implementing virtual process monitoring.

These efforts not only improve product quality but also strengthen structural qualities, promoting dependability, which is essential for demanding applications involving nickel-based superalloy components.

In conclusion, nickel-based superalloys, which are forged through antioxidant manufacturing, are the cornerstone of modern engineering prowess and provide unmatched strength and endurance under pressure.

A future of yet greater innovation and utility in high-performance applications is promised by their ongoing refinement and exploration through cutting-edge methodologies.