In order to increase safety, sustainability, and efficiency, Safetysight Exploration is urging the mining industry to embrace the modern transformation.

For mining companies looking to use the power of modern transformation for safer and more effective operations, SafeSight Exploration Inc. positioned itself as a significant partner in 2017.

SafeSight has discovered over the past six years that appropriate and readily available data are essential for safer and more effective operations. The business has evolved into trailblazers in the collection of data in previously unreachable areas. Mine sites are unable to achieve a correct electric twin without this information and are missing the whole picture.

To reap the rewards of the modern transformation, mining must acknowledge that data management and data mining are the new competences and capabilities.

What is the mining industry’s modern transformation?

Digital transformation in the mining industry describes the fusion of cutting-edge modern technologies and data-driven solutions to transform conventional mining operations. Implementing technologies like Internet of Things ( IoT ) sensors, automation, artificial intelligence ( AI), and data analytics that optimize processes, improve safety, and boost efficiency are all examples of this. Mining companies can increase productivity, lessen climate impact, and make more informed decisions over the course of the overall mining lifecycle by utilizing the power of modern transformation.

the trip to the electronic gold mine

The idea of the modern twin has gained popularity swiftly in 2022 and 2023 because it has the potential to revolutionize conventional mining operations. A modern twin is a computer-generated, ongoing update on real-time data from sensors and IoT devices that mimics the natural mining site’s equipment, geological formations, and processes. The mining industry finds this modern representation to be an extremely valuable tool with a number of important advantages.

Digital twins first and important help mining companies optimize their operations. They offer a thorough, real-time view of the entire mining process, making it possible to spot bottlenecks, inefficiencies, and potential areas for improvement. Companies can make more informed decisions to boost productivity and cut down on downtime by visualizing data.

Safety is yet another important factor. Operators can simulate scenarios using online twins without endangering lives or equipment because they provide a secure environment for testing and training. This improves safety procedures, reduces accidents, and makes the workplace safer.

Digital twins are also valued by the mining sector for their capacity to facilitate forecast maintenance. Companies can anticipate when maintenance is required, reducing unplanned downtime and extending the lifespan of expensive machinery by continually monitoring equipment conditions and performance.

In conclusion, the mining industry considers digital twins to be great because of their potential to optimize operations, enhance safety, and lower costs through data-driven decision-making, making them an essential component of the sector’s effort to achieve efficiency and sustainability.

stages of modern transformation

The mining industry will find an unexpected abundance of online data generated by a variety of new modern high-tech equipment as it continues down the digital twin and digital transformation path. How to properly mine that data and extract the most valuable information nuggets to drive intelligent decision-making and efficient operations will be their challenge.

This issue is certainly brand-new for sectors that are going through a significant electronic transformation. A large portion of Canada’s open sector, particularly Ontario, worked on the digital transformation of criminal justice in the late 1990s and early 2000s. Earlier in the 2000s, the province’s healthcare system underwent a swift digital transformation after this. The pathology was the same in both circumstances. The following were the stages of the pathology:

- changing business drivers necessitating the evolution of technology,

- The availability of cutting-edge, high-tech solutions to address the industry’s call to action

- Eventually, the need for high-speed, reliable infrastructure (5G ) and

- the understanding that mining nowadays requires the development of expertise in data management, collection, and mining. To reap the rewards of the transformation, these novel competences and capabilities are required.

It’s safe to say that the broader industry started embracing these technologies in earnest around the late 2010s and continued to do so into the 2020s. The precise timing of the modern transformation initiatives can vary from one mining company to another. As new technologies and strategies are created and put into practice to meet the changing needs of the mining sector in a rapidly changing world landscape, this modern transformation continues to accelerate and evolve. The sector is currently moving through stage three as this evolution takes place, and it will immediately be completely engulfed in stage four.

overcoming the difficulties of modern data

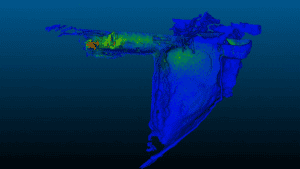

Traditional underground data collection has a constrained reach and range, and the resulting 3D models are missing about 30 % of the information, which is known as” shadow.” Mining operations face a number of difficulties due to shadows produced in mining 3D models:

- Safety concerns: Possible hazards can be hidden by shadows.

- Shadows in 3D models can make own planning and design more difficult.

- Exploration and surveying: According to shadows, data may be false or incomplete.

- Maintenance difficulties: It can be difficult to inspect and maintain infrastructure and equipment in remote areas due to shadows.

In other words, shadows represent uncollectible data, and the absence of data prevents safer and more effective operations from achieving a correct modern twin.

The work of SafeSight

Standard operating procedures are transformed by SafeSight Technology, which also improves working conditions. We have collaborated with forward-thinking world leaders in the mining industry to facilitate that transformation, and in doing so, we have acknowledged that the core of our technological innovations is the collection of complex data.

The organic material for safer and more efficient operations is the data gathered. any of the many and quickly developing mine planning tools ( Deswik, Datamine, MineMax, etc. ) ” Greed in, garbage out,” are only as good as the data that is available.

The shadow and “missing components” that stand in the way of a real digital twin have all but been eliminated by our work and technologies.

most recent data collection

Planning and surveying changed

Survey and Planning are significantly impacted by underwater mapping and modeling using SafeSight’s LiDAR collection tool set. Shadows are removed using SafeSight’s DB4 Underground mapping Drone, DeepTraxx RC truck, and safeScanner, which also doubles productivity and produces 100 % special compliance. Implementing this data collection technology will increase production by$ 1.6 million annually and bring the site closer to a digital twin without missing components.

Digital rescue and emergency response for mine

Emergency data is no longer dependent on the responder’s real location. Responders can gather scene information, search for, and rescue data 200 meters away from the incident using SafeSight’s Emergency Response drone ( ERD ) and Fire Response DeepTraxx. Now that HD Video and HD Thermal Imaging are available for rural data collection, responders can produce digital data that will save lives.

High-fidelity twin shaft

A crucial artery in any site operation is the shaft. Additionally, a modern model of the shaft is necessary for any digital twin to be perfect. A high-fidelity 3D model of the shaft that is correct to one millimeter has been developed and used by SafeSight.

Medial mining underwent change

To help guide the rail and ensure that it never misses the ore body or the target finish point, SafeSight’s MRC Rail Runner offers the ability to independently collect video and a shadow-free 3D model of the raise during development. The online twin can incorporate a precise model of raises while protecting the crews and survey team from harm.

The mining industry’s future of streaming data

Mining operations are looking to switch to LTE ( Long-Term Evolution ) technology and private networks more and more. The transition to personal networks and LTE has many advantages that improve mining operations ‘ effectiveness, security, and total performance.

The need for dependable, high-performance communication, improved safety, effective data handling, reduced quiet, increased security, and compliance with evolving industry standards is what is driving the migration of mining to personal networks and LTE technology. For mining companies looking to modernize their operations and stay competitive in the changing mining landscape, these technologies are becoming essential.

In Q1 of 2024, SafeSight currently intends to take advantage of the upcoming infrastructure and switch our technology to 5G-enabled data collection. What does “underground” mean in this context?

Planning and surveying changed

Imagine how survey, reconciliation, and mine planning would change if survey data gathered underground became accessible shortly after the data collection was finished. In order to manage and manipulate the collected data and make it accessible for the subsequent steps in the development lifecycle, planners and engineers would no more need to wait for survey crews to arrive at the surface. As soon as the data was gathered, they would have it.

Mine rescue and response to an emergency

evaluating the situation

Imagine a situation where real-time streaming of rescue or emergency data was used to assess the scene before emergency crews arrived.

rescue and search

Imagine a real-time HD and infrared video stream being sent to the command and control center during an effective fire or search and rescue operation. Skilled intelligence and incident response support could be provided by experts with access to the network from anywhere in the world. Responders may be able to reach and range far beyond any operating or actual restrictions.

The significance of the modern transformation in the mining industry

SafeSight will keep pushing the boundaries of technology in the mining industry and fostering industry-wide electronic innovation. By transforming conventional practices, the mining industry’s modern transformation holds the promise of a brighter future.

It has the ability to improve sustainability, safety, and operating effectiveness. IoT sensors, automation, AI, and data analytics are just a few of the cutting-edge technologies that help mining companies make data-driven decisions, streamline operations, cut costs. Preventative maintenance and real-time monitoring reduce equipment downtime, which results in increased productivity.

A safer working environment is also a result of increased safety measures, such as remote operation and monitoring.

Additionally, by lessening the industry’s ecological footprint, modern transformation promotes environmental sustainability. These scientific developments put mining on a path to greater competitiveness and long-term viability in an environment that is changing quickly worldwide.