In order to hasten the expansion of the electronic car industry, Cirba Solutions is addressing the issue of lithium-ion battery recycling.

From the estimation of adoption rates to the batteries that power them, energy vehicles are now a hot topic. There are concerns about what to do with a battery after it reaches the end of its original lifespan as well as whether there is much essential mineral supply to manufacture these batteries.

a power plant for recycling batteries

Cirba Solutions is one team in special that is attempting to address those crucial areas. For more than 30 years, this team has been enhancing their network and service capabilities. Cirba Solutions has remained firm throughout the quick development of this technology, expanding its services and processing offerings to meet the market’s demands for battery recycling.

Today’s focus is on lithium-ion batteries ( LIBs ), and a lot of debate centers on whether there are enough essential materials on hand to create the batteries that make LIB the most popular battery chemistry worldwide. According to Cirba Solutions, the answer is to convert used batteries into fresh ones, a method that is frequently used in the lead acid battery market.

converting outdated batteries into fresh ones

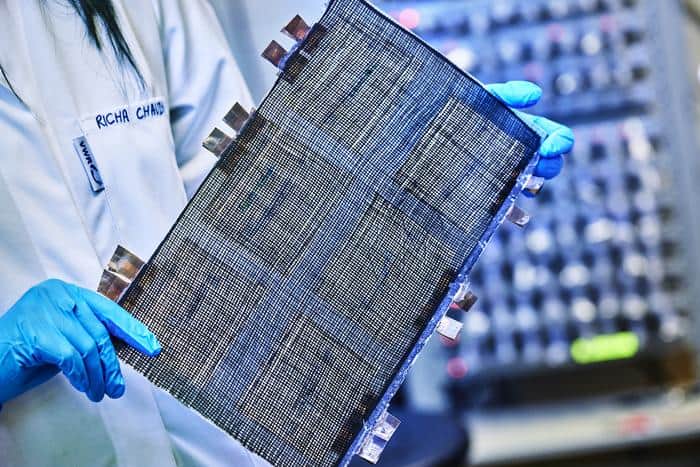

Cirba Solutions is utilizing technological advancements to install hydrometallurgical processing, extracting over 95 % of the important materials, which will be transformed into battery-grade metals through their recycling process, in order to produce novel battery materials from scrap or used batteries. This expands the so-called “black mass,” which has already been created. The materials go through a leaching process after the first step of creating the dark mass, next impurity removal to guarantee high-quality outputs, and finally separation. Each metal undergoes crystallization following separation to produce the battery-grade metals, also known as sulphates.

At their Lancaster, Ohio, facility in the United States, this wonderful new process is first being installed. The Bi- Partisan Infrastructure Law late gave this site over$ 82 million in Department of Energy grants. Over 250 million dollars are anticipated to be invested in the project, which will also add more than 100 new jobs to the local economy.

These materials support producers of cathode active material ( CAM ) as well as precursor materials (PCAM ). By 2030, it is anticipated that cathode demand will increase by 4, 000 GWh in the markets for electric vehicles and energy storage systems .1 Supply shortages for essential minerals are anticipated to continue to present supply chain challenges, with a significant decline in 2028 based on existing projections.

Expansion

While the market for battery recycling is expanding quickly, the source of feedstock is changing from scrap batteries used in manufacturing to end-of-life vehicles, but both markets are experiencing rapid growth. By 2021, recycled materials are expected to supply 24 % of lithium and 33 % of nickel demand. With the growing market and expanded processing capabilities, secondary supply may account for an even higher percentage.

Cirba Solutions has revealed a new location in Columbia, South Carolina, in addition to the Ohio expansion. This new location will be the fifth operating facility in the” US Battery Belt,” an area that has grown as a result of the incentives provided by the Inflation Reduction Act. With everything from manufacturing to recycling, this region stretches from Michigan through Georgia, and States have made sizeable investments in it.

Over the past year, Cirba Solutions has already seen a 30 % increase in the processing of lithium-ion batteries. This growth shows the Company’s solid market position as well as market demand. Cirba Solutions, a long-standing market leader, is committed to sustainable and attentive growth, which is attained by concentrating on enlightening battery recycling. Knowing that Cirba Solutions is a dependable and knowledgeable business partner gives partners and customers peace of mind. We are looking forward to seeing the effect this component of the supply chain will have on a spiral battery supply chains as this market continues to grow and with increased attention.

References

- Benchmark Mineral Intelligence Forecast for the Cathode Q3 2023.