The Technological University of Shannon (TUS) is spearheading initiatives to create low-carbon, circular-lifecycle sustainable packaging solutions to address the global challenge of plastic waste. Under the leadership of Dr. Margaret Brennan-Fournet, TUS’s LIFE Health and Wellbeing Biosciences Research Institute focuses on developing sustainable polymer alternatives that comply with the European Packaging Waste Directive, which mandates responsible plastic packaging by 2030. Key projects include the EcoPlastiC initiative, which aims to create recyclable and biodegradable packaging using innovative depolymerization technology, enabling a “make-unmake-remake” lifecycle. TUS’s proprietary Rex process facilitates the circular recycling of post-consumer PET waste, converting it back into high-quality polymers suitable for food packaging. Additionally, TUS explores methods like bacterial fermentation and green polymer processing to restore materials and reduce environmental footprints. These advancements not only contribute to the reduction of plastic pollution but also offer economically viable solutions for the global food packaging market, which is expected to grow significantly by 2032. TUS continues to invite partnerships to commercialize these groundbreaking green technologies, promoting a sustainable and circular economy for polymer and plastic packaging products.

The Technological University of Shannon is taking initiatives to create circular-lifecycle-friendly, low-carbon cheap sustainable packaging solutions.

In response to the global challenge posed by mounting plastic waste, Technological University of the Shannon (TUS) is leading cutting-edge research to develop food-safe and industrial-grade sustainable polymer alternatives. The seven research institutes at TUS are working in concert under the direction of Vice President of Research, Development, and Innovation Dr. Liam Brown to harness clinical expertise, tactical partnerships, and a commitment to climate responsibility to effect change.

Under the direction of Dr. Margaret Brennan-Fournet, a famous materials scientist based at TUS’s LIFE Health and Wellbeing Biosciences Research Institute in Athlone, TUS has increased its efforts to provide companies with alternatives in light of the recently updated European Packaging &, Packaging Waste Directive, which mandates that a minimum of 55 % of all plastic packaging be responsible by 2030.

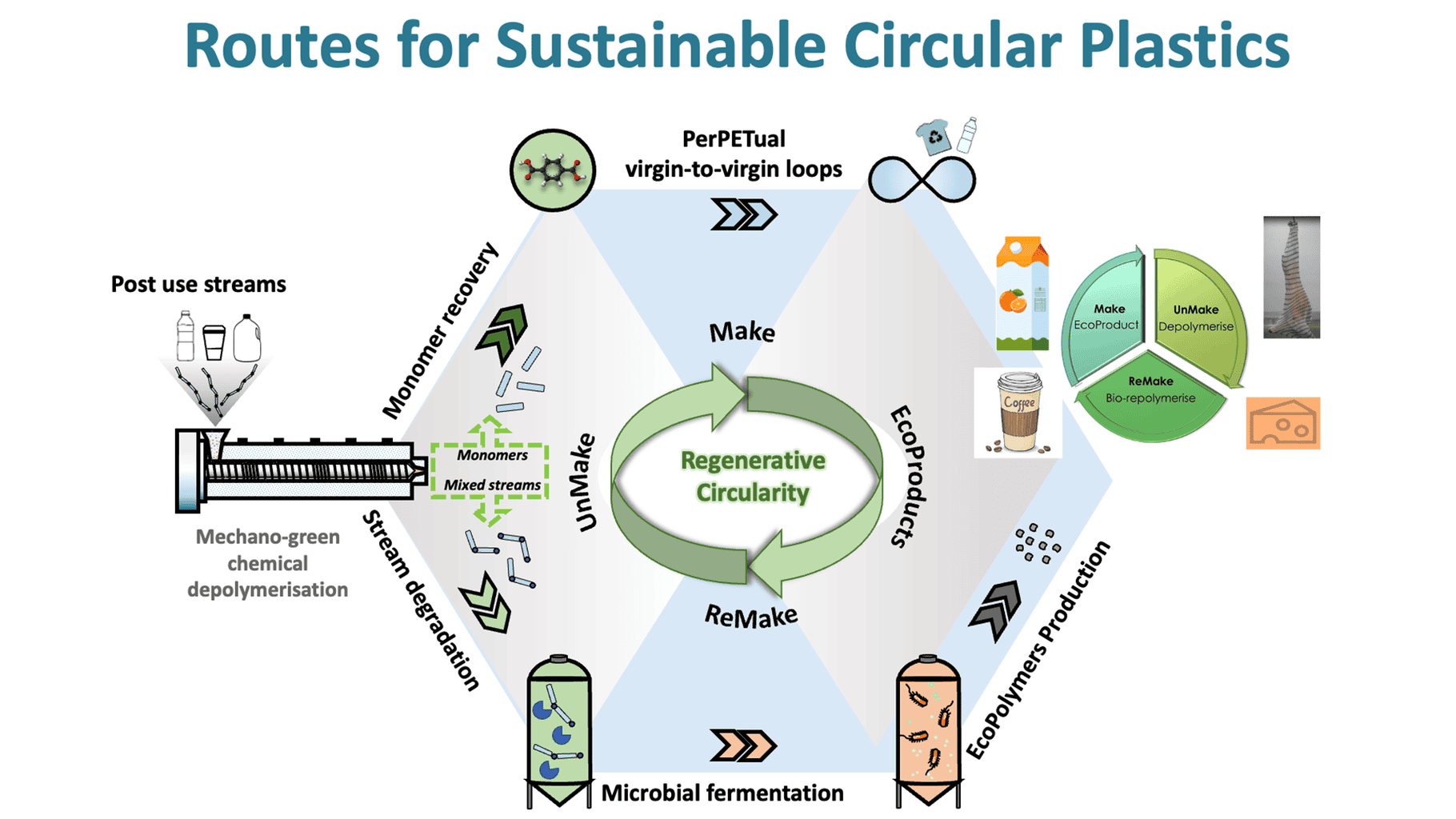

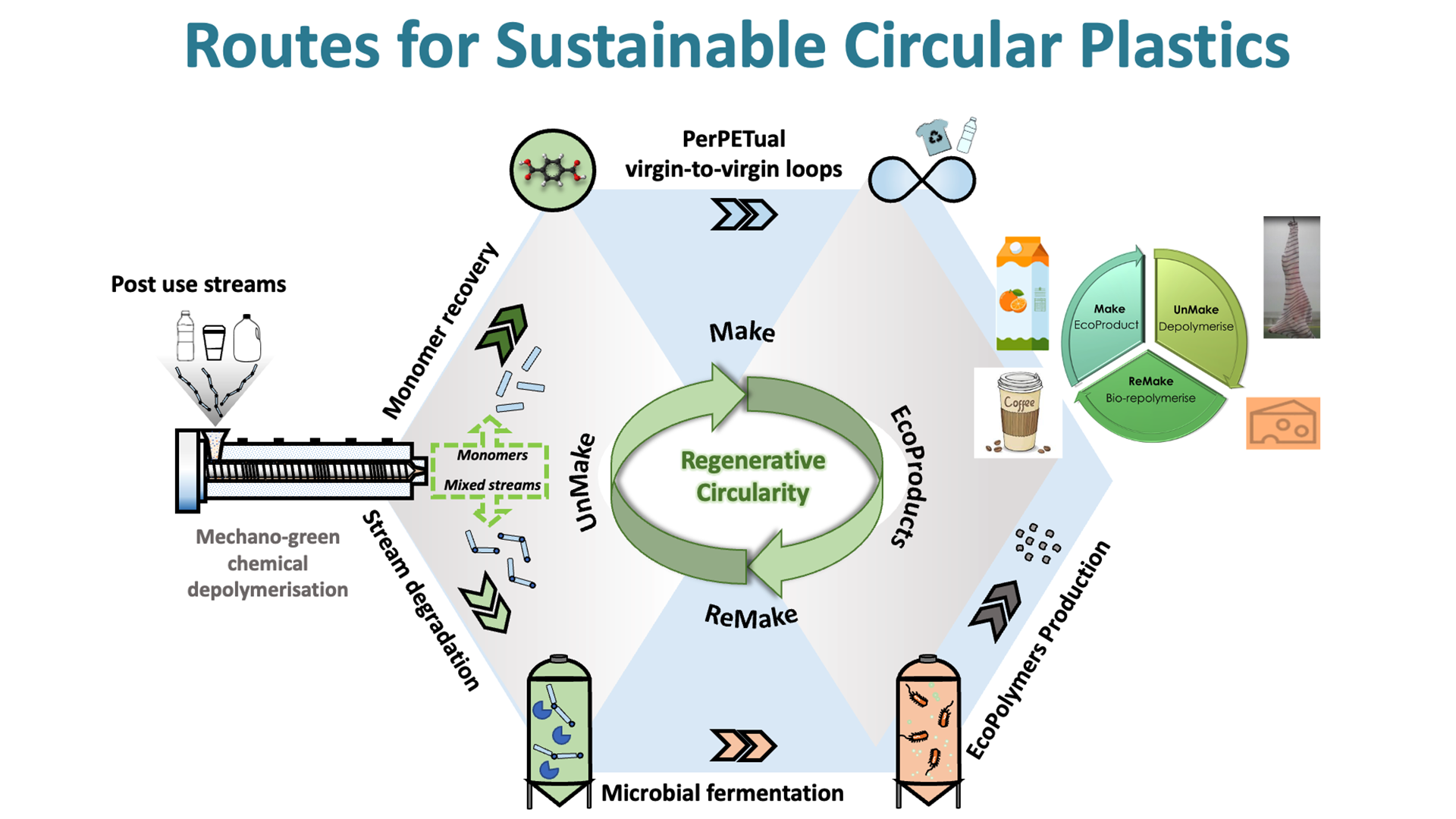

Dr Brennan-Fournet and her team are spearheading initiatives to invent low-carbon industrial-grade plastic packaging solutions through the cross-institute Centre for Polymer Sustainability. These innovations operate within round’ make, unmake and remake’ lifecycles, ensuring sustainability and restorative processes akin to normal ecosystems. By pursuing a high-risk, high-gain creative strategy to cultivate the’ make-unmake-remake’ strategy, the process has the potential for full commercialisation applications available for industry-grade production.

Make: Eternally biodegradable, lasting plastic products manufacturing

The EcoPlastiC project, which is one of TUS’s initiatives, is one of its most important investments and is funded by the highly competitive Western Innovation Council. TUS’s EcoPlastiC project has developed technologies that enable entry into everlasting renewable loops in collaboration with consumers, industry, international partners, and policymakers. For the sustainable food packaging industry, recyclable round plastics and cheap solutions with high performance are being developed as primary alternatives to the latest polluting petroleum-based plastics that are being applied to innovative waste stream fermentation and processing.

Examples include:

- Compared to petro-based EvOH, great O2 barrier packaging layered composites have comparable performance.

- Bioadhesives for paper and plastic packaging sealants that perform similarly to regular artificial adhesives.

TUS’s EcoPlastiC prototypes are designed to operate within entirely round life cycles and can be quickly “made” using brand-new in-house depolymerization technology, followed by “remaking” within ongoing loops. Creative enterprise partners are now able to develop these and other industry-leading products.

UnMake: Post-use product depolymerisation and degradation with the generation of feedstock streams

More bolstering sustainability efforts is TUS’s €2.9m Permanent project, supported by Enterprise Ireland’s Disruptive Technologies Fund. Post-consumer biopolymer and petro-polyesters can now be’ unmade’ through a new disruptive proprietary low-cost, high-yield green reactive extrusion depolymerisation (Rex) processing system.

With continuous” virgin-to-virgin loop” recycling processes that are suitable for all types of PET, spanning pristine grades used in bottles to low-grade pots, tubs, and trays, with no loss of polymer performance, the Rex process provides circularity for the common polymer material Polyethylene Terephthalate (PET).

This has the potential to significantly aid in preventing the fixed resource wasting, landfilling, and recycling of waste plastics in favor of turning them into valuable resources, as well as demonstrating the use of a round plastics model.

To depolymerise post-consumer PET waste, the Rex process can be easily integrated into existing manufacturing lines. These PET precursor monomers can be easily repolymed as virgin PET by producing purified terephthalic acid (PTA) and ethylene glycol (EG), making it suitable for use again in food packaging and beyond.

Expansion of the Rex technology makes it effective for mingled PET streams and other petro- and bio-polyesters. This opens up waste foam resources, allowing them to be used as feedstocks for the production of regeneratable packaging that operates in circular loops. TUS is constantly looking for partners to create spiral lifecycles for PET-based pure and mixed streams.

ReMake: Repolymerisation, bacterial fermentation and green plastic processing

Restorative manufacturing seeks to restore and rejuvenate as well as reduce the environmental footprint of production processes. This can be accomplished in plastic processing by conventional chemical repolymerization in the case of pure monomer streams like PET, or by fermentation and biopolymerization (remake) in the case of mixed feedstocks. The green polymers created are completely compatible with modern and traditional methods of plastic processing and manufacturing, such as porous film co-extrusion, blown film extrusion, and injection moulding, for the production of industrial products for the food packaging and other broader plastics sectors.

TUS is constantly working with foam value chain industries to empower businesses in order to achieve circularity in their products and processes in order to increase the adoption and adoption of green technologies.

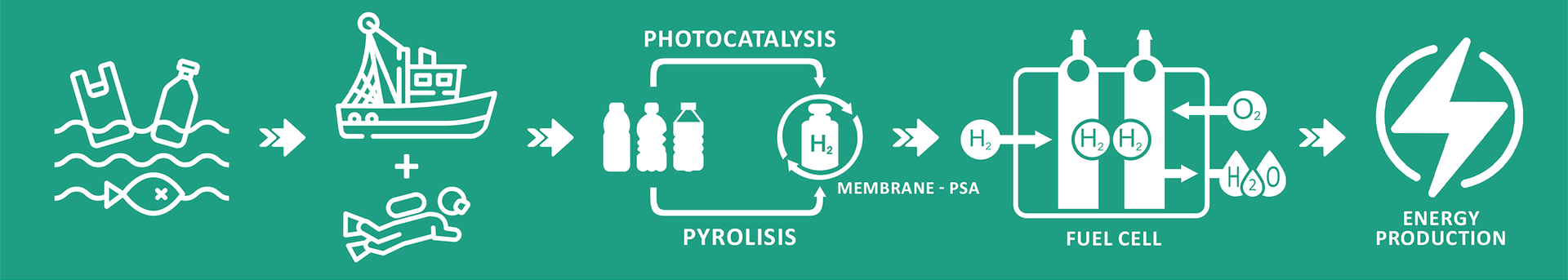

Supporting the violet and natural environment

TUS’s main goal is to promote easily appropriate technologies developed to reduce plastic pollution in oceans, seas, and waterways. TUS is converting linked marine litter and plastic waste into important products, including hydrogen for energy and eco-friendly plastics, in collaboration with partners in the Atlantic Area and the INTERREG PLAST4H2 project.

The potential for lasting packaging created by TUS disruptive technologies is limitless. The global food packaging market was valued at $357 billion in 2022, and it is anticipated to reach a $642 billion market by 2032. This enormous value is stark contrasted by the fact that only 5% of closed-loop plastic food packaging is officially reported to be recycled within the EU.

The most recent developments in renewable technologies at TUS are poised to bring the life cycle of polymers from layered packaging and versatile films that can no longer be economically recycled to date. They aim to determine the most effective path to commercialisation, with a focus on spin-out formation and future partnerships.

Dr. Margaret Brennan-Fournet, a professor at TUS, stated:”Our decades-long expertise in polymer research and commitment to round practices have positioned us exclusively to meet the current and future demands for eco-packaging solutions through the development of green polymer alternatives. Our renewable technologies are certainly only eco-friendly but even economically viable, ready for industry-grade production. To meet their needs, we invite businesses to collaborate with us in developing these round and green technologies for polymer and plastic food packaging products, ensuring a good impact on our environment and economy.”